Things to Consider During Aluminum Die-Casting Processing

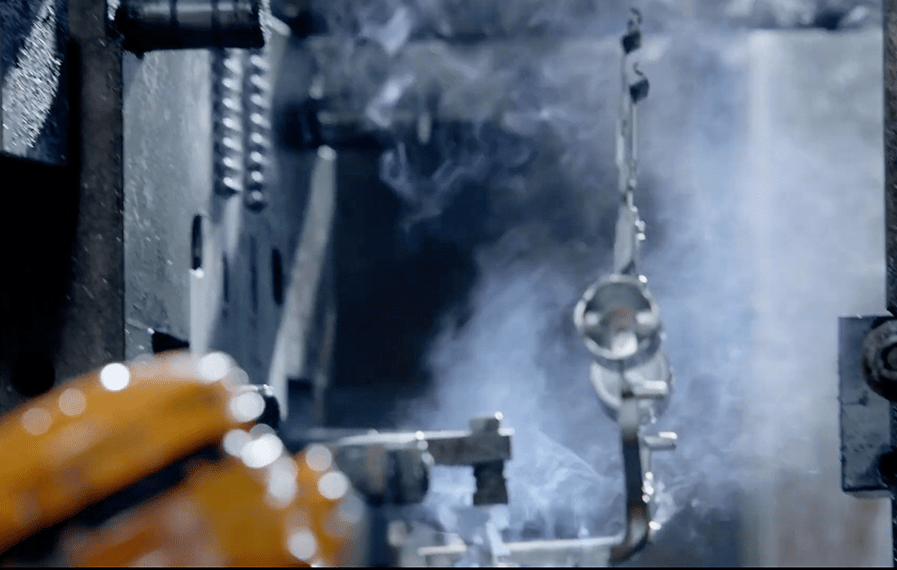

Aluminum die-casting is an intricate and highly precise manufacturing process that involves injecting molten aluminum alloy into a steel mold to create parts with complex geometries and excellent mechanical properties. However, achieving high-quality results requires careful attention to every stage of production. Below are the critical considerations during the aluminum die-casting process:

1. Preparation and Design

Designing the Part:

Before commencing any aluminum die-casting project, it’s essential to carefully design the part and plan out the entire manufacturing process. The design should account for various factors, such as material selection, part geometry, ease of mold release, and any special features like internal holes, threads, or grooves.

Material Selection:

The material used for die-casting—aluminum or its alloys—must be chosen based on the part’s intended use, required strength, and environmental factors. Different aluminum alloys (such as ADC12, A380, or A360) offer varying properties such as strength, corrosion resistance, and casting fluidity, and selecting the right alloy ensures optimal performance of the final product.

Process Planning:

The designer must plan the die-casting process, considering the best casting method (such as high-pressure die-casting or gravity die-casting) and how to manage aspects like material flow, mold cooling, and venting. Planning also includes evaluating the need for any post-casting operations, such as machining, polishing, or surface treatments.

2. Mold Design

Precision and Accuracy:

The design of the mold is a critical factor in achieving the desired quality and precision of the final part. Molds should be designed to accommodate complex shapes while ensuring that parts are produced with consistent dimensions and minimal defects. The mold design must provide adequate venting for gas escape, proper cooling channels to control the rate of cooling, and an efficient gating system that ensures uniform flow of molten metal.

Mold Materials and Durability:

Molds are typically made from high-strength steel or other durable alloys, as they need to withstand the high pressures and temperatures during the casting process. The mold’s ability to resist wear and tear is vital, as molds can become damaged or deformed after repeated use. High-quality, durable mold designs can help reduce production costs by extending the mold's lifespan and improving the consistency of each casting.

Cooling and Shrinkage Considerations:

The cooling rate and pattern in the mold significantly impact the casting’s final properties. Rapid cooling typically results in a harder, stronger part, but it can also cause thermal stresses and shrinkage defects if not carefully controlled. Mold designers must strategically place cooling channels to ensure uniform temperature distribution and reduce the risk of defects like warping, cracking, or dimensional inaccuracies.

3. Temperature Control

Maintaining Proper Metal Temperature:

Temperature control is crucial for ensuring the fluidity of molten aluminum and the uniformity of the casting process. If the molten metal is too cold, it may not properly fill the mold, resulting in incomplete castings or cold shuts. Conversely, if the metal is too hot, it could lead to oxidation, porosity, or other defects that degrade the strength and integrity of the part.

Mold Temperature Control:

Proper mold temperature control is also essential. Too high a mold temperature can lead to excessive die wear and poor part quality, while too low a temperature may cause premature solidification or incomplete filling of the mold. Water-cooling systems or thermal control devices in the mold are often used to maintain an optimal temperature range during the die-casting process.

Controlled Solidification:

Managing how the metal cools and solidifies in the mold is key to minimizing defects like shrinkage porosity, especially in large or thick-walled castings. A well-designed cooling system helps ensure uniform cooling, which minimizes stress and distortion in the final part.

4. Post-Processing

Surface Treatment and Finishing:

After the casting is removed from the mold, it often requires post-processing to achieve the desired surface finish, enhance functionality, or improve durability. Common post-processing steps include:

Grinding and Polishing: To remove any imperfections, such as rough edges, flash, or excess material left from the molding process.

Surface Coating: Including anodizing (for corrosion resistance), powder coating (for durability and aesthetics), or plating (such as chrome or nickel plating for added protection and appearance).

Heat Treatment: Some parts may need to undergo heat treatment (e.g., aging or solution heat treatment) to enhance their mechanical properties, such as increasing strength or hardness.

Machining and Tapping:

For parts requiring tight tolerances or specific threads, machining operations, such as milling, drilling, or tapping, are performed. While aluminum die-casting provides excellent dimensional accuracy, post-casting machining helps to achieve precise final dimensions, ensure proper fit, and complete surface requirements.

5. Quality Control

Dimensional Inspection and Testing:

Rigorous quality control is crucial throughout the aluminum die-casting process to ensure that each part meets its design specifications. This includes dimensional inspections to check that the castings conform to the required tolerances. Coordinate measuring machines (CMM) and optical inspection tools are often used for precision measurements.

Non-Destructive Testing (NDT):

Non-destructive testing methods, such as ultrasonic testing, X-ray inspection, or dye penetrant testing, may be used to identify internal defects such as porosity, cracks, or voids that could affect the part's strength and performance. This is especially important for critical components used in automotive or aerospace applications, where safety and reliability are paramount.

Final Product Testing:

Before shipping, the finished die-cast parts may undergo various tests to assess their functional performance under specific operating conditions. For example, fatigue tests may be conducted to ensure that the parts can withstand repeated stress, or corrosion tests to assess their durability in harsh environments.

Aluminum die-casting is a precise and highly efficient manufacturing method, but the success of the process depends on careful planning, design, and monitoring throughout each stage. From mold design to temperature control, post-processing to quality control, every detail plays a crucial role in producing high-quality, high-performance parts. By focusing on these key considerations, manufacturers can ensure that aluminum die-cast components meet the highest standards of quality, functionality, and durability.

- Aluminum Die-Cast Components for Drones

- Aluminum Die Casting Parts for Low Earth Orbit Satellites

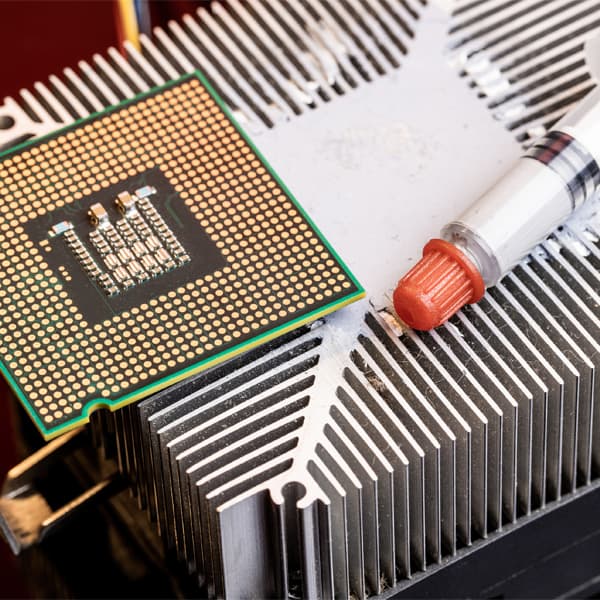

- High-Performance Thermal Components for AI

- From Concept to Mass Production: How Advanced Patent Die Casting Enables Complex Industrial Designs in the AI Era

- Supply Chain Resilience and Localized Manufacturing: Why "Made in Taiwan" Aluminum Die-Casting Parts Are Gaining Favor Post-Pandemic

- New Opportunities in Aluminum Die-Casting Amidst the EV and New Energy Wave: How Lightweighting is Defining the Future of Mobility

- Unveiling the Future of Aluminum Die-Casting: How Industry 4.0 is Revolutionizing Production Efficiency and Quality

- Why Aluminum Alloys Are Preferred for Die-Casting?

- Alunex OEM/ODM Die-Casting Solutions for Automotive, Motorcycle, and Bicycle Parts

- ALUNEX's OEM/ODM Expertise: Tailored Heat Sinks for Your EV Applications

- Die Casting Development Process at ALUNEX

- Things to Consider During Aluminum Die-Casting Processing

- What Industries Can Die-Casting Serve?

- Features of Aluminum Die-Casting

- Why Choose Aluminum Alloy as the Die-Casting Material?

- What is Aluminum Die-Casting?

- Unlocking the Future of Die Casting: The Advantages of CNC Machining for Post-Casting Operations

- Order Issues and Support