Aluminum Die Casting Parts for Low Earth Orbit Satellites

With global low-Earth orbit satellite constellation projects such as Starlink and OneWeb accelerating, a new era of the space economy has arrived. This revolutionary transformation is redefining global communication networks, yet the manufacturing challenges behind it remain largely unseen. Leveraging 30 years of professional experience, Taiwan’s precision casting pioneer ALUNEX has successfully emerged as a key player in the space industry supply chain.

Made in Taiwan, Reaching Space

Under the extreme demands of space-grade components, ALUNEX’s proprietary aluminum alloy die-casting technology demonstrates unique advantages:

- Weather-Resistant Design for Extreme Temperature Fluctuations

Low-Earth orbit satellites circle the Earth every 90 minutes, experiencing sudden temperature swings from -150°C to +150°C. Our specialized heat treatment process and patented alloy formulation ensure that satellite structural components remain dimensionally stable under these conditions, providing reliable protection for communication equipment. - Revolutionary Lightweighting Technology

Every kilogram saved can reduce launch costs by approximately $20,000! We use exclusively developed aerospace-grade and reinforced alloys to achieve 80% higher strength than standard aluminum alloys while reducing weight by 35%, directly translating into cost advantages for our clients. - The Ultimate Expression of Taiwanese Precision Manufacturing

The accuracy of satellite components directly affects communication quality. ALUNEX’s unique Precision Contour Die Casting technology achieves ultra-precise tolerance control of ±0.02 mm, far surpassing the industry standard of ±0.05 mm, ensuring perfect fit and performance of satellite components.

Rooted in Taiwan, Reaching for Space

With more than 50,000 low-Earth orbit satellites expected to be launched globally by 2030, ALUNEX is actively expanding production capacity and increasing investment in aerospace-grade aluminum alloy R&D, continuously strengthening Taiwan’s key position in the global space manufacturing supply chain. From Taichung to space, ALUNEX leverages precision casting technology to support humanity’s space communication dreams, realizing the interstellar value of 'Made in Taiwan.

- Aluminum Die-Cast Components for Drones

- Aluminum Die Casting Parts for Low Earth Orbit Satellites

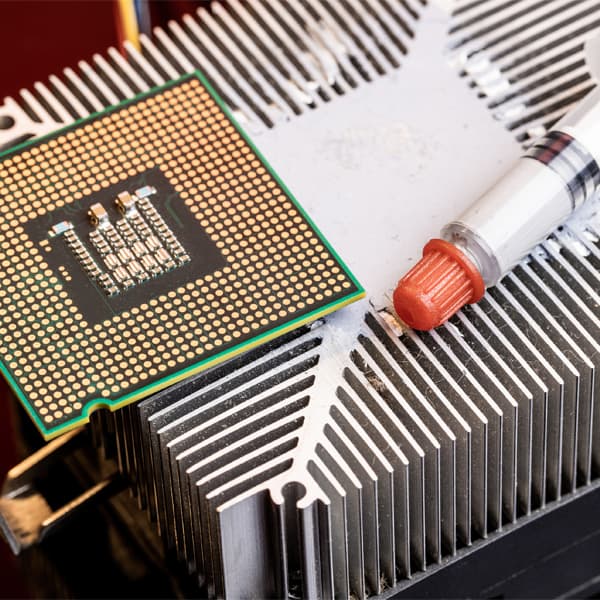

- High-Performance Thermal Components for AI

- From Concept to Mass Production: How Advanced Patent Die Casting Enables Complex Industrial Designs in the AI Era

- Supply Chain Resilience and Localized Manufacturing: Why "Made in Taiwan" Aluminum Die-Casting Parts Are Gaining Favor Post-Pandemic

- New Opportunities in Aluminum Die-Casting Amidst the EV and New Energy Wave: How Lightweighting is Defining the Future of Mobility

- Unveiling the Future of Aluminum Die-Casting: How Industry 4.0 is Revolutionizing Production Efficiency and Quality

- Why Aluminum Alloys Are Preferred for Die-Casting?

- Alunex OEM/ODM Die-Casting Solutions for Automotive, Motorcycle, and Bicycle Parts

- ALUNEX's OEM/ODM Expertise: Tailored Heat Sinks for Your EV Applications

- Die Casting Development Process at ALUNEX

- Things to Consider During Aluminum Die-Casting Processing

- What Industries Can Die-Casting Serve?

- Features of Aluminum Die-Casting

- Why Choose Aluminum Alloy as the Die-Casting Material?

- What is Aluminum Die-Casting?

- Unlocking the Future of Die Casting: The Advantages of CNC Machining for Post-Casting Operations

- Order Issues and Support