The Process of Die Casting

ALUNEX have made significant investments in state-of-the-art equipments to drive our shift toward automated manufacturing. To enhance precision and efficiency, we have integrated a series of advanced six-axis robotic arms from Switzerland’s ABB and Germany’s KUKA into our aluminum die-casting operations. These robotic arms are essential for automating key manufacturing tasks, including casting, coating, grinding, and assembly.

By adopting automated manufacturing, we have been able to achieve faster turnaround times and significantly boost production output. This technology not only accelerates our production processes but also ensures the consistency and high quality of every component, meeting the growing demands of the market.

Raw Material Inspection

We maintain strict oversight of our raw material suppliers, ensuring that only the highest-quality aluminum ingots are used in our production process. By thoroughly vetting and selecting trusted suppliers, we guarantee that the aluminum ingots meet our exacting standards for purity, consistency, and performance. This commitment to quality ensures that every casting produced by ALUNEX upholds the highest levels of strength, durability, and precision.

Raw Material Testing & Analysis

To ensure the highest quality of every batch of aluminum ingots, we conduct comprehensive analysis using advanced spectrometer technology. This allows us to precisely measure the chemical composition of the ingots, ensuring that they meet strict quality standards. Additionally, we perform detailed examinations of the material's microstructure, using metallurgical techniques to identify any potential defects or inconsistencies. By rigorously inspecting both the composition and structure of our raw materials, we guarantee that each batch of aluminum ingots is fully compliant with the required specifications, providing the foundation for producing high-quality die castings.

Aluminum Ingot Melting

We use advanced melting technology to ensure optimal quality in our aluminum die casting process. Our facilities are equipped with the StrikoWestofen central tower melting furnace from Germany, as well as our own Self-Developed Crucible Type Melting and Holding Furnace. These systems are capable of melting different grades of aluminum ingots, tailored to the specific requirements of each casting project. We take great pride in integrating our unique manufacturing techniques, ensuring that every step of the process is carefully designed to meet the precise needs of each client.

In addition to efficient melting, we apply a range of critical techniques to enhance the quality of the molten aluminum. These include fluxing (slag removal), degassing (removal of dissolved gases), and holding/stewing. These processes are essential for preserving the integrity of the aluminum alloy by removing impurities, controlling gas content, and maintaining consistent temperature stability. The result is high-quality molten metal that is perfectly suited for the die casting process, ensuring superior castings for every project.

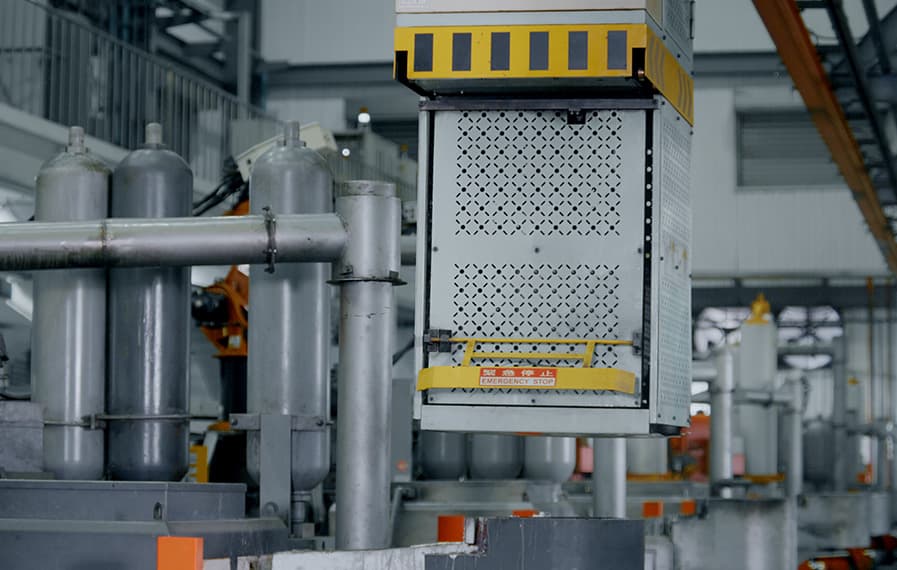

Automated Melt Delivery System

We have deployed a fully automated Melt Delivery System, integrated with our self-developed Holding Furnace, to automate the aluminum melt delivery process. This system ensures precise and consistent melt transfer, while maintaining stable and reliable molten aluminum temperature control throughout the entire process.

The one-cycle automatic operation minimizes human intervention, enhancing overall production efficiency. By automating the melt delivery and holding stages, we not only increase the accuracy of the aluminum casting but also ensure that the melt quality remains consistent throughout the casting cycle. The benefits of this automated system include improved precision, reduced variation, and greater overall consistency, which are crucial for producing high-quality aluminum castings.

Die Casting Manufacturing

We are equipped with a wide variety of Die Casting Machines to meet the diverse needs of our clients. Our facility houses vacuum die casting machines, cold chamber die casting machines, six-axis robotic arms, and more, enabling us to offer a comprehensive range of services tailored to different types of aluminum die casting.

We provide a one-stop aluminum die casting solution, managing every stage of production, from design to delivery. Our aluminum die casting services span a broad tonnage range, from 125 to 800 tonnes, allowing us to efficiently handle both small and large-scale production runs with precision, consistency, and reliability.

Fully Automated Grinding & Stamping

To enhance our manufacturing capabilities, we have integrated six-axis robotic arms from Switzerland’s ABB and Germany’s KUKA into our automated grinding and stamping operations. These advanced robotic systems work seamlessly with our innovative automation equipment designs, ensuring high precision, efficiency, and consistency across each process.

The automated grinding process ensures that every component is finished to exact specifications, with consistent surface quality and minimal variation. Meanwhile, our automated stamping system improves the speed and accuracy of metal shaping, reducing human error and maximizing throughput.

By incorporating these state-of-the-art technologies, we offer our customers faster turnaround times, higher-quality products, and greater cost-efficiency. This automation integration not only optimizes our production capabilities but also strengthens our commitment to delivering superior service and value.

Mechanical Surface Treatments

After the die casting process, we offer a range of mechanical surface treatments designed to optimize both the appearance and performance of the castings. Our services include sandblasting, which effectively cleans and smooths the surface by removing roughness and impurities. Additionally, we provide vibration grinding, a polishing technique that ensures uniformity and enhances the finish of the casting, improving its overall quality.

To further enhance the strength and durability of the aluminum castings, we offer T5 Aluminum Heat Treatment. This heat treatment process increases the mechanical properties of the castings, ensuring they meet the required performance standards. By combining these surface treatments, we ensure that our products not only meet but exceed customer expectations in both quality and performance.

Machining

We have a skilled and experienced machining team that is equipped to perform a wide range of precision turning and milling operations. These processes are critical for achieving the exact dimensions, surface finish, and functional requirements of each part, tailored to its specific application. Whether it's for complex geometries, fine tolerances, or high-performance components, our team ensures that every piece meets the exact specifications set by our clients.

We utilize advanced machinery and cutting-edge technology to perform these machining processes, which include CNC turning, CNC milling, and other specialized techniques. These capabilities allow us to work with various materials, including aluminum alloys, to produce parts with exceptional precision and surface quality. Through our commitment to continuous improvement and a focus on quality control, we ensure that every product not only meets industry standards but also exceeds customer expectations in terms of performance, durability, and appearance.

Surface Treatment

We offer a variety of surface treatment options to enhance both the appearance and durability of our die-cast components. These treatments include powder coating, anodizing, electroplating, and electrophoretic deposition (ED). Each of these processes is designed to improve the aesthetic qualities, corrosion resistance, and overall durability of the castings, ensuring they meet the highest standards of performance and longevity. By applying these advanced surface treatments, we provide our customers with components that not only look great but also stand up to the demands of their specific applications.

Quality Control

Throughout the production process, we enforce a comprehensive series of quality control measures, including IQC (Incoming Quality Control), PQC (Process Quality Control), FQC (Final Quality Control), and OQC (Outgoing Quality Control), to ensure that each product meets the required specifications. These multiple stages of inspection help us maintain the highest standards of quality at every step, from raw material sourcing to final delivery.

Once the casting is solidified, the ejection process begins. The ejection mechanism uniformly pushes the casting out of the tooling, where an extractor clamp transfers it to a conveyor for further processing. After the casting is removed, operators carefully inspect it for defects such as deformation, flow marks, soldering, drag marks, broken pins, shrink marks, cracks, and porosity. If any issues are identified, parameters are promptly adjusted to ensure the next batch meets the highest quality standards.

Shipping and Global Trade

With extensive experience in international trade, we offer flexible shipping options, including sea freight and air freight, to ensure prompt and reliable delivery to our global customers. Our logistics team is committed to managing each shipment efficiently, ensuring that products reach their destinations on time and in perfect condition.

In addition to providing high-quality aluminum die castings, we emphasize the importance of **casting design reviews** with our customers before mold production. This collaborative approach ensures that molds are accurately designed and developed, maximizing the benefits of aluminum alloy die casting while minimizing the risk of future defects.

We also offer a comprehensive range of customize services, including polishing, grinding, hand grinding, drilling, tapping, and CNC machining (turning, milling). Our team is also skilled in applying a variety of surface treatments and coatings to enhance the performance and appearance of the castings. With our unwavering commitment to quality and precision, we have successfully integrated into the supply chains of leading companies across Japan, China, Singapore, the United States, Germany, the United Kingdom, and beyond.