What is Aluminum Die-Casting?

Aluminum die-casting is a widely used metal manufacturing process in which molten aluminum alloys are injected into a precisely engineered metal mold under high pressure to form complex and highly accurate aluminum alloy products. This method is highly valued for producing high-precision components with intricate shapes, excellent surface finishes, and robust mechanical properties. Below are four key processes and features that define aluminum die-casting:

1. Basic Principles and Process of Aluminum Die-Casting

The aluminum die-casting process involves several fundamental steps and techniques. The core principles of aluminum die-casting include:

Mold Flow Analysis: Before starting production, mold flow analysis is performed to simulate the behavior of molten metal during the injection process. This helps in identifying potential flow issues and optimizing mold design to achieve optimal results.

Mold Design: A crucial step where molds are designed based on product requirements. The design takes into account factors such as cooling channels, venting, and gating systems to ensure the efficient flow of molten metal into the mold.

Selection of Die-Casting Molding Process: The type of die-casting machine and molding method—whether hot-chamber or cold-chamber die-casting—are selected based on the size, complexity, and material of the component being produced.

Melting and Injection of Aluminum Alloy: The chosen aluminum alloy is melted in a furnace and injected into the mold cavity under high pressure. This high-pressure injection ensures that even the most intricate mold cavities are filled completely, capturing fine details and achieving tight tolerances.

High-Pressure Filling, Cooling, and Solidification: After injection, the molten aluminum fills the mold under pressure, followed by rapid cooling and solidification. Once solidified, the mold is opened, and the part is ejected. The result is a highly precise component that is ready for further processing, such as machining or surface treatment.

2. Advantages and Characteristics of Aluminum Die-Casting

Aluminum die-casting offers several significant advantages compared to other manufacturing methods:

High Precision: Die-casting allows for the production of complex and accurate parts with tight tolerances, making it ideal for industries that require high-precision components, such as automotive, aerospace, and electronics.

Smooth Surface Finish: The die-casting process typically results in parts with smooth, high-quality surface finishes, reducing the need for additional post-production finishing work.

Excellent Strength-to-Weight Ratio: Aluminum is well-known for its excellent strength-to-weight ratio, making die-cast parts lightweight yet durable. This is particularly advantageous in applications where weight reduction is critical, such as in automotive and electric vehicle parts.

Rapid Production Cycle: Aluminum die-casting enables faster production cycles compared to other manufacturing processes, such as machining or forging. This makes it a cost-effective choice for high-volume production runs.

Design Flexibility: The process can accommodate intricate and complex shapes, enabling the design of parts that might otherwise be difficult or expensive to manufacture using traditional methods.

3. Applications and Products of Aluminum Die-Casting

Aluminum die-casting is used across a wide range of industries due to its versatility and efficiency. Common applications include:

Automotive Parts: Aluminum die-casting is extensively used in the automotive industry to produce lightweight, durable components such as engine blocks, transmission housings, structural frames, and wheels.

Electric Vehicle (EV) Components: As electric vehicles become more popular, the demand for lightweight and efficient components increases. Aluminum die-casting is ideal for producing parts such as battery enclosures, motor housings, and chassis components for EVs.

Aerospace Components: The aerospace industry relies on aluminum die-casting for precision parts such as engine components, structural brackets, and housings, which must meet strict performance and weight requirements.

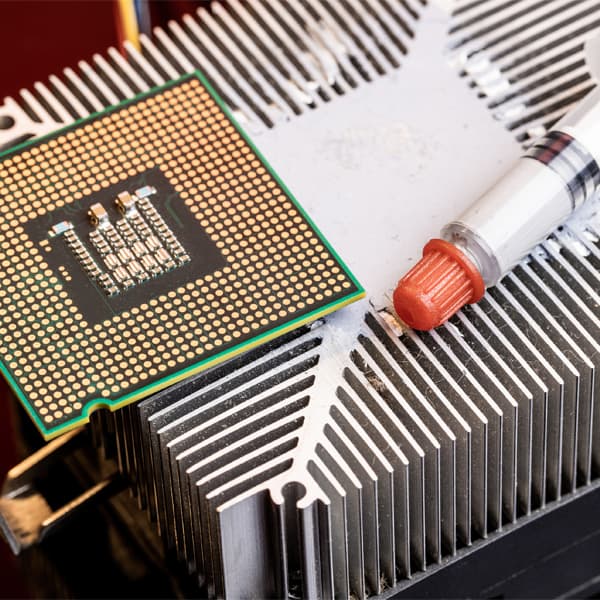

Electronics and Communication Equipment: Many electronic devices, such as computer cases, phone housings, and connectors, are manufactured using aluminum die-casting due to its ability to form intricate designs and its thermal conductivity properties.

Surveillance and Optical Equipment: Aluminum die-casting is commonly used in the production of camera housings, light fixtures, and other components in surveillance and optical equipment, providing strength, durability, and corrosion resistance.

Industrial Machinery: Components like gears, motor housings, and machine frames are often made using aluminum die-casting, benefiting from its ability to withstand high stress and mechanical loads.

4. Die-Casting Process Technology and Material Selection

The success of an aluminum die-casting project depends on choosing the appropriate process technologies and selecting the right materials for the job:

Die-Casting Machine Selection: The type of die-casting machine (cold-chamber or hot-chamber) is chosen based on factors such as the material being used, the size of the parts, and the production volume. Cold-chamber machines are typically used for alloys that are more reactive, such as aluminum, while hot-chamber machines are used for materials like zinc.

Mold Material Design: The mold material must be designed to withstand the high temperatures and pressures involved in the die-casting process. Typically, molds are made from high-strength tool steels that can endure repeated cycles of heating and cooling without deforming or cracking.

Aluminum Alloy Selection: The choice of aluminum alloy is crucial for achieving the desired mechanical properties, corrosion resistance, and thermal conductivity of the final product. Different alloys are selected based on the requirements of the specific application, such as A380 for its strength and A360 for its fluidity and corrosion resistance.

Material Properties: The selection of material properties, such as tensile strength, hardness, and ductility, is tailored to meet the functional requirements of the product. For example, parts used in high-temperature environments may require alloys with enhanced thermal stability and resistance to fatigue.

Post-Casting Treatment: After the casting process, various post-treatment processes like heat treatment, surface finishing, or machining may be applied to further enhance the properties of the part, including improving surface finish, hardness, or corrosion resistance.

- Aluminum Die-Cast Components for Drones

- Aluminum Die Casting Parts for Low Earth Orbit Satellites

- High-Performance Thermal Components for AI

- From Concept to Mass Production: How Advanced Patent Die Casting Enables Complex Industrial Designs in the AI Era

- Supply Chain Resilience and Localized Manufacturing: Why "Made in Taiwan" Aluminum Die-Casting Parts Are Gaining Favor Post-Pandemic

- New Opportunities in Aluminum Die-Casting Amidst the EV and New Energy Wave: How Lightweighting is Defining the Future of Mobility

- Unveiling the Future of Aluminum Die-Casting: How Industry 4.0 is Revolutionizing Production Efficiency and Quality

- Why Aluminum Alloys Are Preferred for Die-Casting?

- Alunex OEM/ODM Die-Casting Solutions for Automotive, Motorcycle, and Bicycle Parts

- ALUNEX's OEM/ODM Expertise: Tailored Heat Sinks for Your EV Applications

- Die Casting Development Process at ALUNEX

- Things to Consider During Aluminum Die-Casting Processing

- What Industries Can Die-Casting Serve?

- Features of Aluminum Die-Casting

- Why Choose Aluminum Alloy as the Die-Casting Material?

- What is Aluminum Die-Casting?

- Unlocking the Future of Die Casting: The Advantages of CNC Machining for Post-Casting Operations

- Order Issues and Support