Why Choose Aluminum Alloy as the Die-Casting Material?

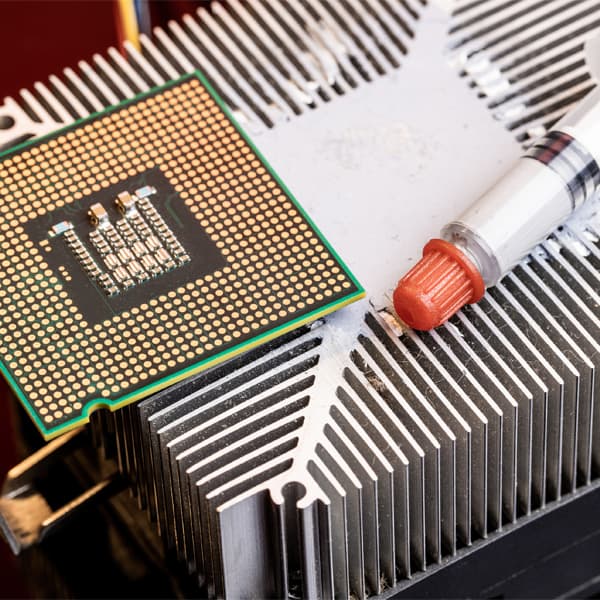

Alunex primarily utilize aluminum alloys for die-casting due to their exceptional properties, which make them ideal for a wide range of applications. Aluminum alloys are lightweight, durable, and offer excellent corrosion resistance, making them an optimal choice for various industries, including automotive, aerospace, electronics, and machinery. These alloys also have excellent thermal conductivity, which is essential for many high-performance components.

We follow international standards set by the International Aluminum Association (JIS/AA/ASTM/DIN) to ensure the quality and consistency of the materials we use. The most commonly used aluminum alloys for die-casting in our production process include:

- ADC12 (A383): Known for its good fluidity and excellent castability, ADC12 is widely used in the automotive and industrial sectors. It is particularly favored for producing parts that require complex shapes and fine details. This alloy has a balanced mix of strength, ductility, and corrosion resistance, making it suitable for a broad range of applications.

- ADC10 (A380): A380 is one of the most popular aluminum alloys for die-casting, primarily used in automotive and industrial applications. It offers high strength, good dimensional stability, and excellent pressure tightness. This alloy is particularly valued for its ability to withstand high mechanical stresses, making it ideal for engine parts, transmission housings, and other critical components that require durability and precision.

- ADC3 (A360): A360 is a highly fluid aluminum alloy known for its excellent castability and corrosion resistance. It is frequently used for components exposed to harsh environmental conditions, such as outdoor or marine applications. This alloy offers superior resistance to corrosion and high strength at lower weights, making it suitable for parts requiring excellent wear resistance, like engine blocks, pump housings, and similar components.

- ADC6 (A514): A514 is a high-strength aluminum alloy known for its ability to withstand high pressure and mechanical stresses. It is used for parts that need enhanced strength without sacrificing weight. A514 is often used in critical applications such as aerospace, heavy machinery, and automotive components where performance, durability, and toughness are essential.

Article Search

Category

Popular Articles

- Aluminum Die-Cast Components for Drones

- Aluminum Die Casting Parts for Low Earth Orbit Satellites

- High-Performance Thermal Components for AI

- From Concept to Mass Production: How Advanced Patent Die Casting Enables Complex Industrial Designs in the AI Era

- Supply Chain Resilience and Localized Manufacturing: Why "Made in Taiwan" Aluminum Die-Casting Parts Are Gaining Favor Post-Pandemic

- New Opportunities in Aluminum Die-Casting Amidst the EV and New Energy Wave: How Lightweighting is Defining the Future of Mobility

- Unveiling the Future of Aluminum Die-Casting: How Industry 4.0 is Revolutionizing Production Efficiency and Quality

- Why Aluminum Alloys Are Preferred for Die-Casting?

- Alunex OEM/ODM Die-Casting Solutions for Automotive, Motorcycle, and Bicycle Parts

- ALUNEX's OEM/ODM Expertise: Tailored Heat Sinks for Your EV Applications

- Die Casting Development Process at ALUNEX

- Things to Consider During Aluminum Die-Casting Processing

- What Industries Can Die-Casting Serve?

- Features of Aluminum Die-Casting

- Why Choose Aluminum Alloy as the Die-Casting Material?

- What is Aluminum Die-Casting?

- Unlocking the Future of Die Casting: The Advantages of CNC Machining for Post-Casting Operations

- Order Issues and Support