Aluminum Die-Cast Components for Drones

With the widespread application of drone technology in logistics, agriculture, defense, and surveying, the lightweight design and high precision of drone components have become key to improving flight endurance, payload capacity, and safety. ALUNEX focuses on the design and manufacturing of aerospace-grade aluminum-magnesium die-cast components, providing durable and lightweight solutions for the drone industry.

Advantages of ALUNEX’s Aluminum Die-Cast Components for Drones

- Lightweight, High-Strength Structure: Using aerospace-grade AL-Mg-Si series aluminum-magnesium alloys, which offer an exceptional strength-to-weight ratio, we increase structural strength by over 35% while significantly reducing airframe weight. With CAE-assisted design optimizing the internal support structure, we achieve the best balance of strength and weight, extending drone flight time and lowering energy consumption.

- Structural Stability and Durability: Featuring excellent vibration resistance and corrosion resistance, our components adapt to a variety of complex flight environments. Single-piece casting technology integrates multiple functional structures, significantly reducing assembly joints and overall weight, thereby enhancing overall reliability.

- Precision Thin-Wall Technology: Die-cast wall thickness can be reduced to as thin as 0.80 mm, ensuring excellent strength while maintaining lightweight design, meeting the strict precision and structural strength requirements of drones.

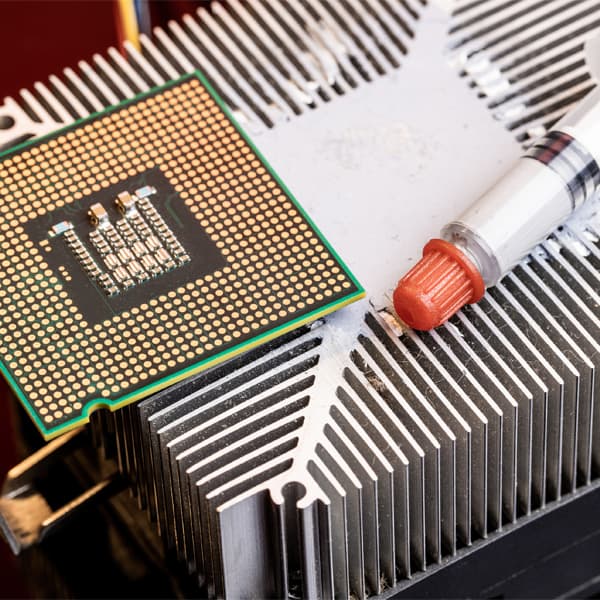

ALUNEX leverages advanced aluminum die-casting technology, combining high-strength materials with excellent corrosion resistance to ensure that critical drone components operate reliably under high loads and harsh environments, enhancing overall performance and service life. Our product line includes drone airframe structures, motor mounts, power system housings, camera and gimbal brackets, battery compartments, heat dissipation modules, as well as landing gear and protective covers, supporting a wide range of commercial and industrial drone applications.

- Aluminum Die-Cast Components for Drones

- Aluminum Die Casting Parts for Low Earth Orbit Satellites

- High-Performance Thermal Components for AI

- From Concept to Mass Production: How Advanced Patent Die Casting Enables Complex Industrial Designs in the AI Era

- Supply Chain Resilience and Localized Manufacturing: Why "Made in Taiwan" Aluminum Die-Casting Parts Are Gaining Favor Post-Pandemic

- New Opportunities in Aluminum Die-Casting Amidst the EV and New Energy Wave: How Lightweighting is Defining the Future of Mobility

- Unveiling the Future of Aluminum Die-Casting: How Industry 4.0 is Revolutionizing Production Efficiency and Quality

- Why Aluminum Alloys Are Preferred for Die-Casting?

- Alunex OEM/ODM Die-Casting Solutions for Automotive, Motorcycle, and Bicycle Parts

- ALUNEX's OEM/ODM Expertise: Tailored Heat Sinks for Your EV Applications

- Die Casting Development Process at ALUNEX

- Things to Consider During Aluminum Die-Casting Processing

- What Industries Can Die-Casting Serve?

- Features of Aluminum Die-Casting

- Why Choose Aluminum Alloy as the Die-Casting Material?

- What is Aluminum Die-Casting?

- Unlocking the Future of Die Casting: The Advantages of CNC Machining for Post-Casting Operations

- Order Issues and Support