Unlocking the Future of Die Casting: The Advantages of CNC Machining for Post-Casting Operations

In the world of die casting, precision, efficiency, and flexibility are paramount, and the integration of CNC machining into the post-casting process is revolutionizing the industry. This advanced technology is quickly becoming the go-to solution for enhancing the quality, speed, and versatility of aluminum die-cast parts. But what exactly makes CNC machining such a game-changer? Let's dive into the key advantages it brings to the post-casting process.

Precision Beyond Compare

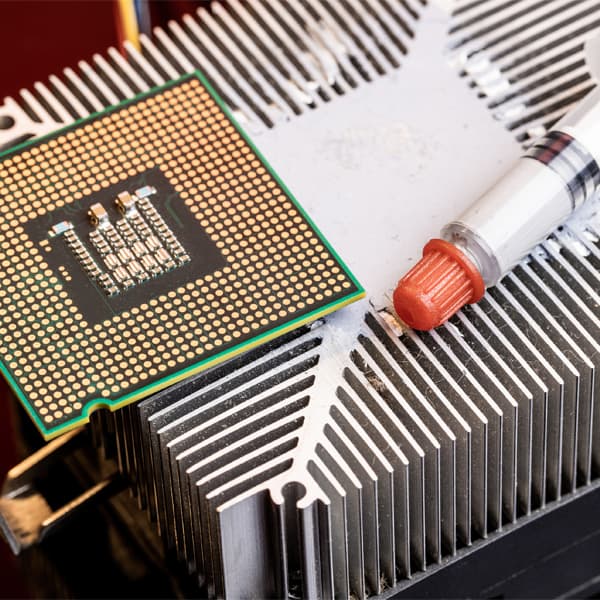

One of the standout benefits of CNC machining is its exceptional precision. Unlike traditional manual machining methods, CNC machines are computer-controlled, ensuring that each cut, drill, and finish is executed with incredible accuracy. This allows manufacturers to meet tight tolerances and ensure that each part adheres to the exact specifications required for its intended application. Whether it’s fine-tuning the dimensions or achieving intricate designs, CNC machining guarantees that the final product aligns perfectly with the customer’s needs.

Unmatched Flexibility and Versatility

The versatility of CNC machining is another game-changing advantage. Whether you're working with different materials, complex designs, or large production runs, CNC machines can be easily programmed to accommodate a wide range of casting requirements. From small, intricate parts to large, robust components, CNC machines handle it all with ease. This flexibility makes them ideal for industries that demand high precision across various applications, including automotive, aerospace, and medical devices.

Efficiency That Drives Cost Savings

In addition to precision and versatility, CNC machining significantly boosts efficiency. With automated processes that require minimal manual intervention, CNC machines dramatically reduce production time and labor costs. The ability to run multiple machines simultaneously, coupled with the automation of processes such as drilling, milling, and turning, allows manufacturers to meet tight deadlines without compromising on quality. This translates into faster turnaround times and cost-effective production, benefiting both manufacturers and customers alike.

Tailored Customization for Unique Needs

Every casting project has its unique requirements, and with CNC machining, customization becomes easier than ever. Whether it’s altering the surface finish, adjusting dimensions, or adding specific features like threads or holes, CNC machining allows for high levels of customization. Manufacturers can quickly adjust parameters to meet the specific needs of each customer, providing a tailored solution for each casting. This capability is particularly valuable for industries where design flexibility and custom finishes are crucial to meeting functionality and aesthetic demands.

The Future of Die Casting is CNC Machining

By integrating CNC machining into post-casting operations, manufacturers can significantly improve the quality, consistency, and efficiency of their products. With its unparalleled precision, adaptability, and cost-effectiveness, CNC machining is not just a trend – it’s the future of the die casting industry. As more manufacturers adopt this technology, the possibilities for innovative, high-quality, and cost-effective die-cast products are limitless.

ALUNEX CNC Machining Services: Precision and Expertise in Every Part

With over 30 years of experience in the die-casting industry, ALUNEX has built a reputation as one of Taiwan’s leading manufacturers of high-precision aluminum and aluminum alloy die-casting products. Specializing in delivering superior die-casting technology and exceptional services, we cater to a broad range of industries, including automotive, medical equipment, agricultural machinery, optical lenses, pneumatic tools, power tools, and construction materials.

We understand that precision is critical, which is why we offer advanced CNC machining services to ensure that every part meets the highest quality standards. Our machining capabilities include turning and milling, performed using state-of-the-art FANUC machines from Japan. With an impressive dimensional accuracy of up to 0.02mm, we are able to produce parts with intricate details and tight tolerances. Whether you need custom-made components or specific finishing touches, ALUNEX provides reliable, high-precision CNC machining services tailored to meet the exact specifications of our customers. This level of precision ensures that each component performs optimally, meeting both functional and aesthetic requirements. For more details, please contact us or visit our CNC service page.

- Aluminum Die-Cast Components for Drones

- Aluminum Die Casting Parts for Low Earth Orbit Satellites

- High-Performance Thermal Components for AI

- From Concept to Mass Production: How Advanced Patent Die Casting Enables Complex Industrial Designs in the AI Era

- Supply Chain Resilience and Localized Manufacturing: Why "Made in Taiwan" Aluminum Die-Casting Parts Are Gaining Favor Post-Pandemic

- New Opportunities in Aluminum Die-Casting Amidst the EV and New Energy Wave: How Lightweighting is Defining the Future of Mobility

- Unveiling the Future of Aluminum Die-Casting: How Industry 4.0 is Revolutionizing Production Efficiency and Quality

- Why Aluminum Alloys Are Preferred for Die-Casting?

- Alunex OEM/ODM Die-Casting Solutions for Automotive, Motorcycle, and Bicycle Parts

- ALUNEX's OEM/ODM Expertise: Tailored Heat Sinks for Your EV Applications

- Die Casting Development Process at ALUNEX

- Things to Consider During Aluminum Die-Casting Processing

- What Industries Can Die-Casting Serve?

- Features of Aluminum Die-Casting

- Why Choose Aluminum Alloy as the Die-Casting Material?

- What is Aluminum Die-Casting?

- Unlocking the Future of Die Casting: The Advantages of CNC Machining for Post-Casting Operations

- Order Issues and Support