Features of Aluminum Die-Casting

Aluminum die-casting is a highly efficient and versatile manufacturing process that offers numerous advantages for producing high-precision, lightweight, and durable components. Here’s a deeper dive into the specific features of aluminum die-casting and why it is often the material of choice for many industries:

1. Lightweight

Aluminum alloys are naturally lightweight metals, which makes aluminum die-cast parts significantly lighter compared to components made from other materials, such as steel or cast iron. This characteristic is particularly beneficial in industries where weight reduction is critical, such as in automotive and aerospace applications.

In automotive design, for instance, reducing the weight of parts directly contributes to improved fuel efficiency, better handling, and enhanced overall performance of vehicles. Likewise, in the aerospace industry, lightweight components help improve fuel efficiency and reduce operational costs. Furthermore, the lightweight nature of aluminum die-casting is beneficial in sporting equipment, electronics, and consumer goods where ease of use and portability are key considerations.

2. High Strength

Despite its lightness, aluminum die-casting offers excellent strength-to-weight ratio. Aluminum die-cast parts are known for their ability to withstand significant mechanical stresses without adding unnecessary weight. This combination of strength and lightness makes them ideal for components that must endure high load-bearing conditions while maintaining performance and durability.

The strength of aluminum die-cast parts can be further enhanced by selecting the appropriate aluminum alloy (such as ADC10 or A380) and by applying post-casting treatments such as heat treatment or surface finishing. This makes aluminum die-casting highly suitable for automotive engine parts, transmission housings, aerospace structural components, and other heavy-duty applications where strength is a top priority.

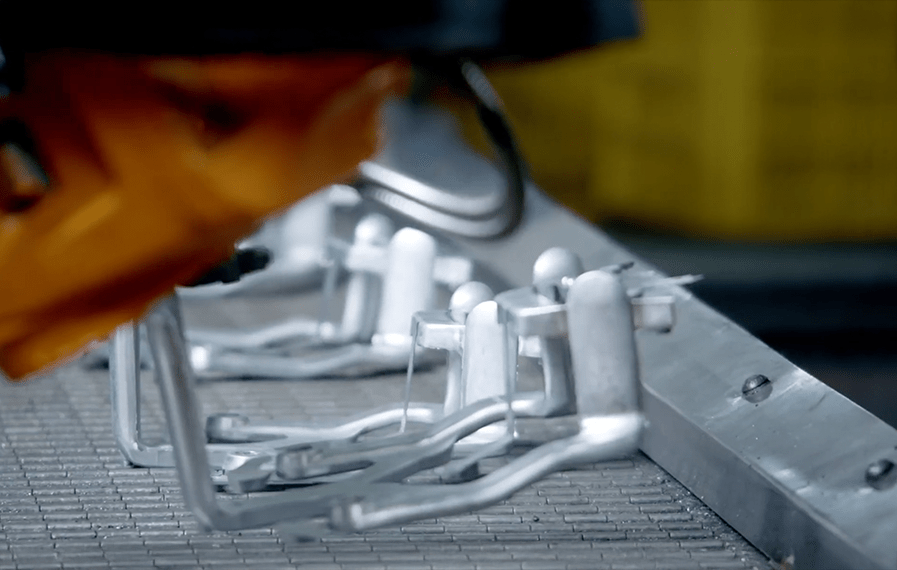

3. Complex Shapes

One of the standout features of the die-casting process is its ability to produce highly complex geometries and intricate shapes. The aluminum die-casting process can easily accommodate parts with thin walls, complex internal cavities, detailed contours, and fine details that would be difficult or expensive to achieve using other manufacturing methods, such as machining or forging.

Additionally, aluminum die-casting allows for near-net-shape production, meaning that parts are cast to their final form with minimal need for additional machining or finishing. This can significantly reduce production costs, especially for high-volume runs, and shorten manufacturing lead times. The ability to create complex shapes in one step also allows for design flexibility, enabling engineers to innovate and optimize product designs.

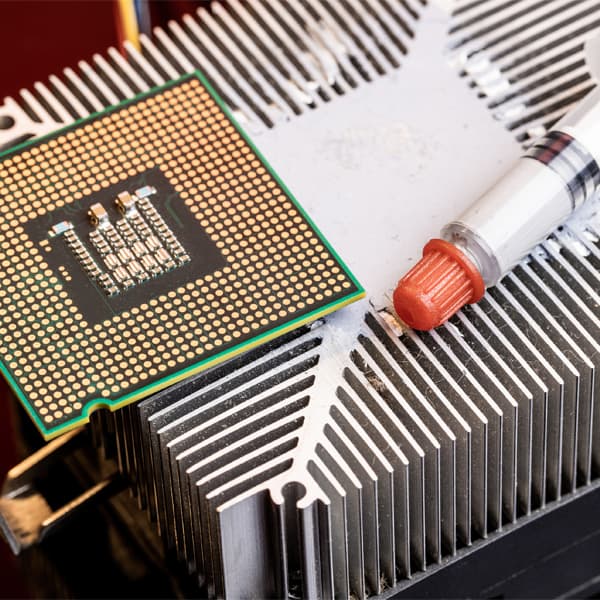

4. Excellent Surface Smoothness

Aluminum die-cast parts are known for their high-quality surface finishes. The casting process itself results in smooth, polished surfaces that typically require little additional surface treatment. This is particularly advantageous in industries where aesthetic appearance and surface integrity are crucial, such as electronics housings, consumer products, and decorative components.

The smooth surface finish also improves the functional performance of parts, especially in applications where friction, wear, or sealing are concerns. Furthermore, a smooth surface minimizes the need for additional post-processing, such as polishing or grinding, thus lowering overall production costs. This surface quality is one of the reasons aluminum die-casting is preferred for parts exposed to high wear and tear, like brake components or valve bodies.

5. Good Corrosion Resistance

Aluminum alloys naturally form a protective oxide layer on their surface when exposed to air. This oxide layer provides excellent resistance to corrosion in many different environments, including moisture, salt, and acidic conditions. As a result, aluminum die-cast parts are highly durable and have a long service life, even in harsh environments.

The corrosion resistance of aluminum makes it an ideal material for marine applications, outdoor equipment, and parts exposed to the elements, such as automotive exteriors or electronic enclosures. Moreover, aluminum die-cast parts are often used in aerospace, automotive, and industrial machinery where components must maintain their integrity and functionality in corrosive environments.

Dimensional stability is another benefit of aluminum die-casting. The material maintains its shape and dimensions even under significant stress, temperature fluctuations, or prolonged exposure to moisture. This stability is crucial in maintaining the precision and accuracy of the final product, reducing the risk of deformation or warping over time, which is vital for high-precision applications.

Why Choose Aluminum Die-Casting?

In summary, aluminum die-casting offers a unique combination of lightness, strength, design flexibility, excellent surface finish, and corrosion resistance, making it one of the most versatile and reliable manufacturing methods for producing high-quality parts. From automotive and aerospace components to electronics and consumer products, aluminum die-casting provides the ideal balance of performance and cost-effectiveness, making it the material of choice for industries that demand both high performance and low weight.

- Aluminum Die-Cast Components for Drones

- Aluminum Die Casting Parts for Low Earth Orbit Satellites

- High-Performance Thermal Components for AI

- From Concept to Mass Production: How Advanced Patent Die Casting Enables Complex Industrial Designs in the AI Era

- Supply Chain Resilience and Localized Manufacturing: Why "Made in Taiwan" Aluminum Die-Casting Parts Are Gaining Favor Post-Pandemic

- New Opportunities in Aluminum Die-Casting Amidst the EV and New Energy Wave: How Lightweighting is Defining the Future of Mobility

- Unveiling the Future of Aluminum Die-Casting: How Industry 4.0 is Revolutionizing Production Efficiency and Quality

- Why Aluminum Alloys Are Preferred for Die-Casting?

- Alunex OEM/ODM Die-Casting Solutions for Automotive, Motorcycle, and Bicycle Parts

- ALUNEX's OEM/ODM Expertise: Tailored Heat Sinks for Your EV Applications

- Die Casting Development Process at ALUNEX

- Things to Consider During Aluminum Die-Casting Processing

- What Industries Can Die-Casting Serve?

- Features of Aluminum Die-Casting

- Why Choose Aluminum Alloy as the Die-Casting Material?

- What is Aluminum Die-Casting?

- Unlocking the Future of Die Casting: The Advantages of CNC Machining for Post-Casting Operations

- Order Issues and Support