New Opportunities in Aluminum Die-Casting Amidst the EV and New Energy Wave: How Lightweighting is Defining the Future of Mobility

The global Electric Vehicle (EV) and New Energy Vehicle (NEV) industries are experiencing unprecedented growth, heralding a century-defining transformation in the automotive sector. Market forecasts predict that annual EV sales will continue to surge in the coming years. This signifies not just a revolution in powertrain systems, but a comprehensive reshaping of vehicle design and manufacturing philosophies.

In this green revolution, "lightweighting" has emerged as the core driver of vehicle design and manufacturing. It is a critical strategy that not only effectively extends driving range and optimizes energy efficiency but also shapes the very future of new energy mobility.

Aluminum die-casting technology, with its outstanding lightweight properties, excellent thermal dissipation performance, and exceptional dimensional accuracy, plays a pivotal role in this transformation. It offers innovative solutions to meet the demands for lightweighting and high performance, particularly in the design and manufacturing of battery modules, motor housings, and structural body components.

The Rapid Growth of the Global EV Market: An Urgent Demand for Lightweighting

The rapid expansion of the electric vehicle (EV) market is being driven by new energy technologies, the advancement of carbon-neutral policies, and growing consumer preferences for sustainable, high-performance vehicles. However, EVs currently face three core challenges:

- Enhancing Range: Vehicle weight directly impacts battery consumption and driving range, making weight reduction a crucial solution. Every kilogram saved translates into increased range, helping to alleviate consumer “range anxiety.”

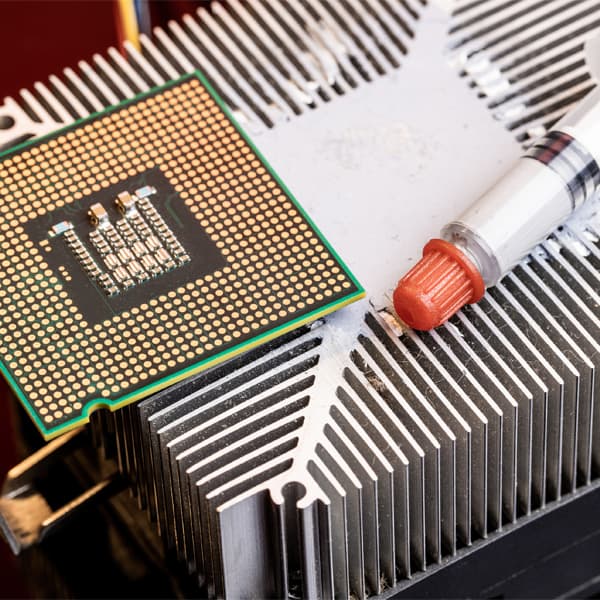

- Optimizing Thermal Management: EV batteries, motors, and electronic control systems generate significant heat during high-speed operation. Efficient heat dissipation is essential to ensure stable performance, extend component lifespan, and maintain optimal vehicle operation.

- Structural Strength and Safety: Achieving lightweight construction must not compromise safety. EVs must still provide robust protection in the event of collisions to ensure passenger safety.

Aluminum alloys, with their high strength, low density, excellent heat dissipation, and corrosion resistance, are considered the ideal materials for lightweighting solutions. Furthermore, aluminum die casting technology can produce ultra-thin, structurally stable, and complex components, perfectly meeting the diverse performance and design requirements of modern EVs.

ALUNEX's Technical Advantages: Meeting the Demands of the EV Industry

As a technical leader in the aluminum die-casting field, ALUNEX deeply understands the demands of the EV market for innovative materials and manufacturing processes. We have established a leading position through the following strengths:

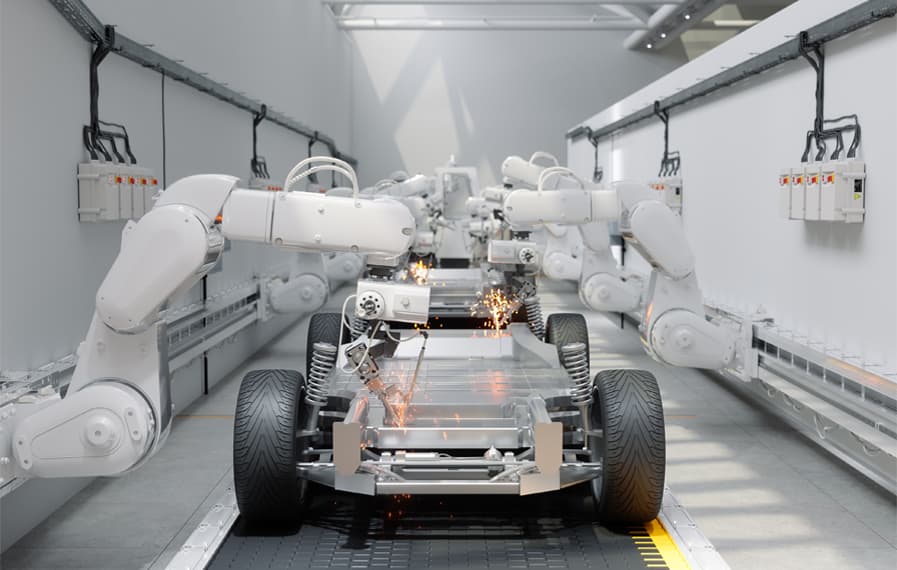

- High-Precision Die-Casting and Intelligent Production Lines: We utilize world-class high-pressure die-casting machines and intelligent management solutions to ensure every production step achieves superior dimensional accuracy and surface quality, with precision in some cases reaching the micron level. The operation of our automated production lines not only boosts efficiency but also minimizes defect rates, guaranteeing the highest strength and stability for every single product.

- Leadership in Material Technology: We specialize in the development and application of high-strength aluminum alloys, ensuring that our die-cast products deliver exceptional resistance to deformation and outstanding durability while remaining lightweight. This meets our clients' stringent requirements for dimensional stability and safety. Our proprietary processing technology has been proven to increase material strength by up to 20% while maintaining excellent thermal conductivity.

- Professional Customized Solutions: Whether it's for battery enclosures or motor housings, ALUNEX provides professionally tailored products designed to meet specific customer needs. We partner with our clients to solve their most pressing challenges related to lightweighting and thermal efficiency, delivering solutions that are engineered for performance.

Future Trends in Aluminum Die Casting for Electric Vehicles

The application potential of aluminum die casting in the electric vehicle sector continues to expand, and several key technology trends deserve attention:

- The Rise of Integrated Die Casting (Giga Casting): Technologies such as integrated die casting, exemplified by "Giga Casting," are driving a new revolution in automotive manufacturing. This approach enables the consolidation of multiple structural parts (such as the rear underbody) into a single large component, significantly reducing the number of parts needed in a vehicle. The result is higher assembly efficiency, greater product consistency, and enhanced body rigidity and safety. Ultimately, it enables substantial improvements in production efficiency, cost reduction, and vehicle performance.

- Circular Economy and Sustainable Materials: With the growing focus on sustainability in EV manufacturing, the recyclability of aluminum has become a significant advantage. In the future, greater emphasis on recycling and reusing die-cast aluminum products will promote the circular economy model and help manufacturers comply with increasingly strict energy-saving and emission regulations.

Integrating Aluminum Die Casting with New Energy Mobility

The rise of electric vehicles (EVs) and new energy technologies is redefining the future of mobility. As a cornerstone for lightweighting and efficient manufacturing, aluminum die casting has become a key driver of industry transformation. With the continued release of EV market potential, adopting ALUNEX’s advanced aluminum die casting solutions will empower your business to stay ahead in both technology and market competition.

We warmly invite R&D, design, and procurement teams in the EV and NEV industries—as well as suppliers of batteries, motors, and electronic control systems—to connect with ALUNEX. Let us work together to explore the limitless possibilities of lightweight design and aluminum die casting innovation for the future of new energy vehicles.

- Aluminum Die-Cast Components for Drones

- Aluminum Die Casting Parts for Low Earth Orbit Satellites

- High-Performance Thermal Components for AI

- From Concept to Mass Production: How Advanced Patent Die Casting Enables Complex Industrial Designs in the AI Era

- Supply Chain Resilience and Localized Manufacturing: Why "Made in Taiwan" Aluminum Die-Casting Parts Are Gaining Favor Post-Pandemic

- New Opportunities in Aluminum Die-Casting Amidst the EV and New Energy Wave: How Lightweighting is Defining the Future of Mobility

- Unveiling the Future of Aluminum Die-Casting: How Industry 4.0 is Revolutionizing Production Efficiency and Quality

- Why Aluminum Alloys Are Preferred for Die-Casting?

- Alunex OEM/ODM Die-Casting Solutions for Automotive, Motorcycle, and Bicycle Parts

- ALUNEX's OEM/ODM Expertise: Tailored Heat Sinks for Your EV Applications

- Die Casting Development Process at ALUNEX

- Things to Consider During Aluminum Die-Casting Processing

- What Industries Can Die-Casting Serve?

- Features of Aluminum Die-Casting

- Why Choose Aluminum Alloy as the Die-Casting Material?

- What is Aluminum Die-Casting?

- Unlocking the Future of Die Casting: The Advantages of CNC Machining for Post-Casting Operations

- Order Issues and Support