Die Casting Development Process at ALUNEX

We take pride in our meticulous approach to aluminum die casting development. Each step of the process is carefully executed to ensure that the final product meets both our customers’ specifications and the highest industry standards. Our die casting development process involves several key stages, all aimed at ensuring the accuracy, functionality, and quality of each aluminum die-cast part we produce.

1. Customer Consultation & Requirement Analysis

The process begins with a detailed consultation with the customer. During this initial phase, we work closely with the client to understand the requirements, specifications, and intended use of the product. We review the design drawings and discuss important details, such as material choice, part geometry, tolerances, and any unique challenges related to the project. Based on this information, we provide a comprehensive quotation and timeline for the project. This ensures that both parties are aligned on expectations before moving forward.

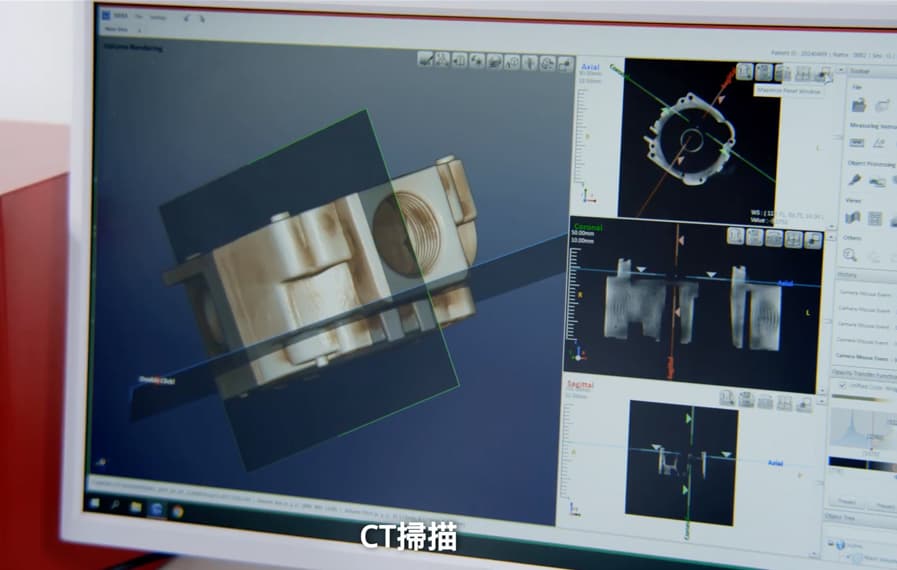

2. Pre-Production Design & Feasibility Analysis

Once the project details are finalized, we conduct a thorough pre-production analysis, which includes reviewing the design from a manufacturability perspective. Our team of expert engineers performs a Mold Flow Analysis (MFA) to simulate the casting process and identify potential issues such as air traps, hot spots, or flow imbalances in the mold. This step helps to predict possible defects in the cast part and allows us to make design adjustments before mold production begins. By analyzing the design’s flow behavior, we optimize the mold to improve efficiency, reduce costs, and prevent defects during the manufacturing process.

3. Mold Design & Manufacturing

Once the design has been validated and optimized, we proceed to the mold design and manufacturing phase. Using the insights gained from the mold flow analysis, we develop a custom mold that is specifically tailored to the product’s specifications. ALUNEX employs advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) systems to ensure the mold is precisely engineered. During this stage, we take great care to ensure that the mold material, structure, and cooling channels are optimized for the casting process.

The mold is fabricated using high-precision machining equipment to ensure durability and long-term performance. This stage requires meticulous attention to detail to ensure that the mold will produce high-quality, accurate parts during the production cycle.

4. Prototype Production & Validation

After the mold is completed, we conduct a series of trial runs to produce initial prototypes. These test parts help us verify the mold’s functionality and check whether the casting meets all specifications in terms of dimensional accuracy, surface finish, and mechanical properties. Our engineers perform rigorous quality checks and physical testing to evaluate the performance of the aluminum die castings, ensuring that they meet customer expectations.

5. Process Failure Mode and Effects Analysis (PFMEA)

Once the prototypes are validated, we conduct a PFMEA (Process Failure Mode and Effects Analysis) to systematically identify any potential risks in the production process. This analysis helps us identify and address any process-related issues that could affect the final quality or lead to product defects. By pinpointing and addressing potential failures early on, we improve the manufacturing process and ensure that we can achieve consistent, high-quality results throughout the production run.

6. Small-Batch Production & Process Optimization

Once the prototypes are validated, we conduct a PFMEA (Process Failure Mode and Effects Analysis) to systematically identify any potential risks in the production process. This analysis helps us identify and address any process-related issues that could affect the final quality or lead to product defects. By pinpointing and addressing potential failures early on, we improve the manufacturing process and ensure that we can achieve consistent, high-quality results throughout the production run.

7. Full-Scale Mass Production

Once we have validated the production process and made necessary adjustments, we move to the full-scale production phase. At this stage, we begin large-volume manufacturing, where we produce the final die-cast parts in the required quantities. We continue to use advanced monitoring systems to ensure that each part meets stringent quality standards. Throughout the production run, we conduct regular inspections and testing to maintain high standards of consistency and precision.

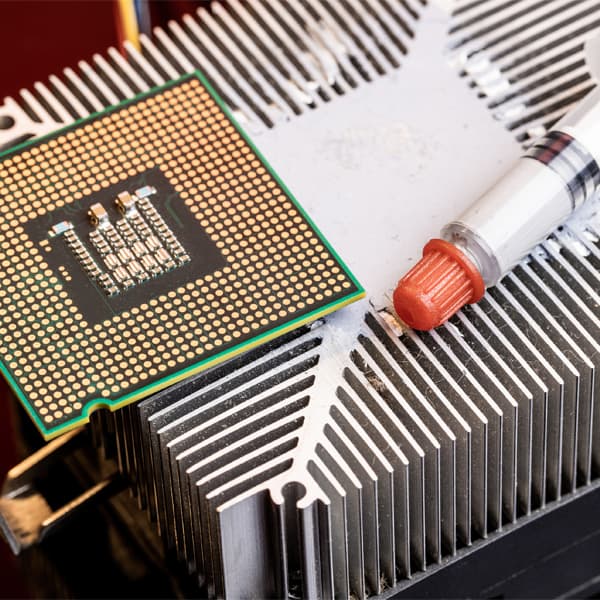

8. Final Quality Control & Delivery

Before delivery, each batch of aluminum die-cast parts undergoes thorough quality control checks. Our experienced quality control team inspects each part for dimensional accuracy, surface quality, and any potential defects. We use advanced measurement technologies, including Coordinate Measuring Machines (CMM) and optical inspection systems, to verify that all components are within tolerance and meet customer specifications.

Once the parts have passed quality inspections, they are carefully packaged and prepared for delivery. We ensure that the parts are securely packed and shipped to meet the customer’s preferred delivery schedule, whether through air or sea freight, depending on the urgency and destination.

Ongoing Support & Continuous Improvement

ALUNEX is committed to delivering superior products and services. Throughout the entire process, from design to delivery, our dedicated team works closely with customers to ensure that the parts meet their exact specifications. We also believe in continuous improvement and actively seek feedback from clients to refine and enhance our processes for future projects.

By combining advanced technology, engineering expertise, and a customer-focused approach, ALUNEX ensures the successful development of high-precision aluminum die-cast parts, delivering excellent performance and durability across a wide range of industries. For more information, please contact via the email address [email protected].

- Aluminum Die-Cast Components for Drones

- Aluminum Die Casting Parts for Low Earth Orbit Satellites

- High-Performance Thermal Components for AI

- From Concept to Mass Production: How Advanced Patent Die Casting Enables Complex Industrial Designs in the AI Era

- Supply Chain Resilience and Localized Manufacturing: Why "Made in Taiwan" Aluminum Die-Casting Parts Are Gaining Favor Post-Pandemic

- New Opportunities in Aluminum Die-Casting Amidst the EV and New Energy Wave: How Lightweighting is Defining the Future of Mobility

- Unveiling the Future of Aluminum Die-Casting: How Industry 4.0 is Revolutionizing Production Efficiency and Quality

- Why Aluminum Alloys Are Preferred for Die-Casting?

- Alunex OEM/ODM Die-Casting Solutions for Automotive, Motorcycle, and Bicycle Parts

- ALUNEX's OEM/ODM Expertise: Tailored Heat Sinks for Your EV Applications

- Die Casting Development Process at ALUNEX

- Things to Consider During Aluminum Die-Casting Processing

- What Industries Can Die-Casting Serve?

- Features of Aluminum Die-Casting

- Why Choose Aluminum Alloy as the Die-Casting Material?

- What is Aluminum Die-Casting?

- Unlocking the Future of Die Casting: The Advantages of CNC Machining for Post-Casting Operations

- Order Issues and Support