Unveiling the Future of Aluminum Die-Casting: How Industry 4.0 is Revolutionizing Production Efficiency and Quality

In today's increasingly competitive global manufacturing landscape, traditional aluminum die-casting technology is facing unprecedented challenges. From continually rising labor costs and a lack of flexibility in production scheduling to increasingly stringent demands for quality and precise tolerances, every aspect tests a company's adaptability and market competitiveness.

For manufacturers in high-tech industries such as automotive, electronics, and optics—sectors that demand high performance, superior quality, and technological innovation—overcoming these bottlenecks to achieve transformative growth has become critical for sustainable development. The answer lies within the wave of "Industry 4.0."

Industry 4.0 is not just a concept; it is a complete smart manufacturing solution that deeply integrates digitalization, automation, and intelligence to fundamentally reshape traditional production models. When this revolutionary force is injected into the aluminum die-casting industry, a revolution in efficiency, quality, and precision begins. While traditional die-casting processes offer cost-effectiveness, their limitations—such as insufficient production efficiency, unstable yield rates, and difficulty meeting the rigorous demands of high-precision manufacturing—become increasingly apparent in the face of complex designs and a hyper-competitive market. The arrival of Industry 4.0 is injecting new vitality into the aluminum die-casting sector, transforming the traditional craft into a smart manufacturing model defined by high efficiency and high quality.

When Robotic Arms Meet Die-Casting: How ABB & KUKA Are Reshaping Intelligent Production

To achieve intelligent die-casting, the core lies in introducing a stable, efficient, and precise automation system. In this domain, the technologies from global industrial robotics giants ABB and KUKA have become the key engines driving this industrial upgrade. By seamlessly integrating these cutting-edge robotic arm technologies into the die-casting production line, ALUNEX has successfully constructed a complete, automated die-casting workstation, enabling truly intelligent production.

From the automatic feeding of aluminum ingots, precise opening and closing of the mold, and accurate injection of molten aluminum, to the extraction and stamping of the finished product, and even the subsequent cooling, deburring, and CNC precision machining—every step is seamlessly connected and executed by ABB and KUKA robotic arms.

These high-precision, tireless "steel employees" not only perform highly repetitive tasks 24/7 but also execute every production command with a level of stability and accuracy unattainable by humans. This is not a simple replacement of manpower; it represents a comprehensive optimization and re-engineering of the entire production process.

How Does Automated Die-Casting Deliver Overwhelming Advantages?

Integrating Industry 4.0 concepts into the die-casting process yields comprehensive benefits, successfully transforming aluminum die-casting from a labor-intensive to a technology-intensive industry. This evolution delivers several core advantages:

- Significant Enhancement in Production Efficiency and Cost Optimization

An automated production line breaks the limitations of traditional manual scheduling, operating continuously at an optimized rhythm that dramatically shortens the production cycle. Data shows that after implementing Industry 4.0 solutions, production efficiency can increase by an average of over 35%, while simultaneously reducing the production time per unit and significantly lowering the unit cost of each part. Automation also reduces direct labor costs and eliminates issues related to worker fatigue and fluctuations in efficiency. - Unmatched Stability in Precision Manufacturing and Radical Error Reduction

In high-precision fields like automotive aluminum components and electronic accessories, stability is the ultimate benchmark for casting quality. Through precise programming and sensor monitoring, an automated die-casting system ensures that every action is executed flawlessly, eliminating human error at the source and reducing error rates by more than 40%.

Whether it is the first casting or the ten-thousandth, the system maintains a consistent quality standard, achieving exceptionally high precision of up to ±0.05mm. By utilizing online inspection and analysis, the system can identify process instabilities in real-time, proactively triggering alarms or corrective actions, which ultimately reduces the defect rate and increases the overall production yield. - Translating Technical Superiority into Market Competitiveness

High-efficiency and high-quality die-casting technology empowers manufacturers to break through production bottlenecks and respond more rapidly to market demands. This capability—whether it's meeting the stringent requirements for aluminum structural parts from top-tier automakers or perfecting the minute details of electronic accessories—helps companies stand out in a crowded market.

In a fiercely competitive environment, technological innovation translates directly into a competitive advantage, enabling manufacturers who adopt Industry 4.0 die-casting to quickly adapt to market changes and deliver lighter, more precise aluminum alloy components.

A Vision for the Future: Partnering for a New Era of Smart Die-Casting

The rapid advancement of Industry 4.0 will continue to bring transformative changes to the manufacturing sector, and aluminum die-casting, as an indispensable part of high-tech industries, is embracing unprecedented opportunities for growth. With the introduction of more advanced technologies, the die-cast products of the future are poised to meet even higher technical standards and market demands.

If you are seeking solutions to your aluminum die-casting challenges or wish to be a pioneer in adopting Industry 4.0 technologies on your production line, ALUNEX is ready to provide expert consultation and comprehensive solutions. Our goal is to leverage technological innovation to position your business at the technological forefront of the market, achieving a dual leap in both efficiency and quality.

Let us chart the future blueprint of aluminum die-casting together and welcome the dawn of the new smart manufacturing era.

- Aluminum Die-Cast Components for Drones

- Aluminum Die Casting Parts for Low Earth Orbit Satellites

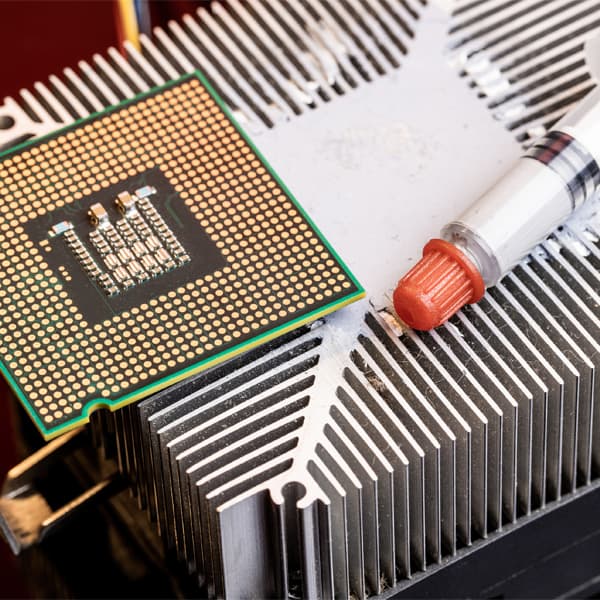

- High-Performance Thermal Components for AI

- From Concept to Mass Production: How Advanced Patent Die Casting Enables Complex Industrial Designs in the AI Era

- Supply Chain Resilience and Localized Manufacturing: Why "Made in Taiwan" Aluminum Die-Casting Parts Are Gaining Favor Post-Pandemic

- New Opportunities in Aluminum Die-Casting Amidst the EV and New Energy Wave: How Lightweighting is Defining the Future of Mobility

- Unveiling the Future of Aluminum Die-Casting: How Industry 4.0 is Revolutionizing Production Efficiency and Quality

- Why Aluminum Alloys Are Preferred for Die-Casting?

- Alunex OEM/ODM Die-Casting Solutions for Automotive, Motorcycle, and Bicycle Parts

- ALUNEX's OEM/ODM Expertise: Tailored Heat Sinks for Your EV Applications

- Die Casting Development Process at ALUNEX

- Things to Consider During Aluminum Die-Casting Processing

- What Industries Can Die-Casting Serve?

- Features of Aluminum Die-Casting

- Why Choose Aluminum Alloy as the Die-Casting Material?

- What is Aluminum Die-Casting?

- Unlocking the Future of Die Casting: The Advantages of CNC Machining for Post-Casting Operations

- Order Issues and Support