Why Aluminum Alloys Are Preferred for Die-Casting?

Aluminum alloys offer several key advantages that make them the material of choice for die-casting:

1. Lightweight

Aluminum’s low density means that products made from aluminum alloys are lightweight, which is critical for applications in the automotive and aerospace industries, where reducing weight contributes to energy efficiency and performance.

2. Excellent Corrosion Resistance

Aluminum alloys naturally form a protective oxide layer on their surface, which provides excellent resistance to corrosion, even in harsh environments.

3. Good Thermal Conductivity

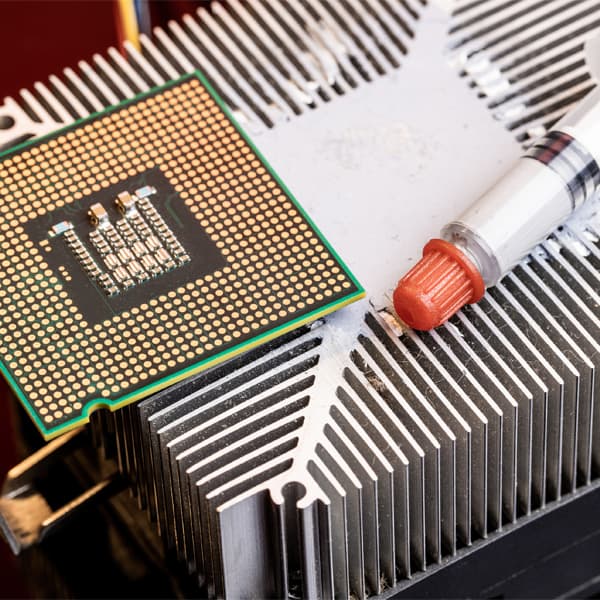

Aluminum alloys are excellent at dissipating heat, making them ideal for parts exposed to high temperatures, such as engine blocks, heat exchangers, and components used in high-performance electronics.

4. Strength-to-Weight Ratio

Aluminum alloys provide a strong, durable structure while keeping weight to a minimum. This is especially beneficial for parts that need to be strong enough to withstand mechanical stresses but lightweight enough for efficient handling and use.

5. Versatility in Manufacturing

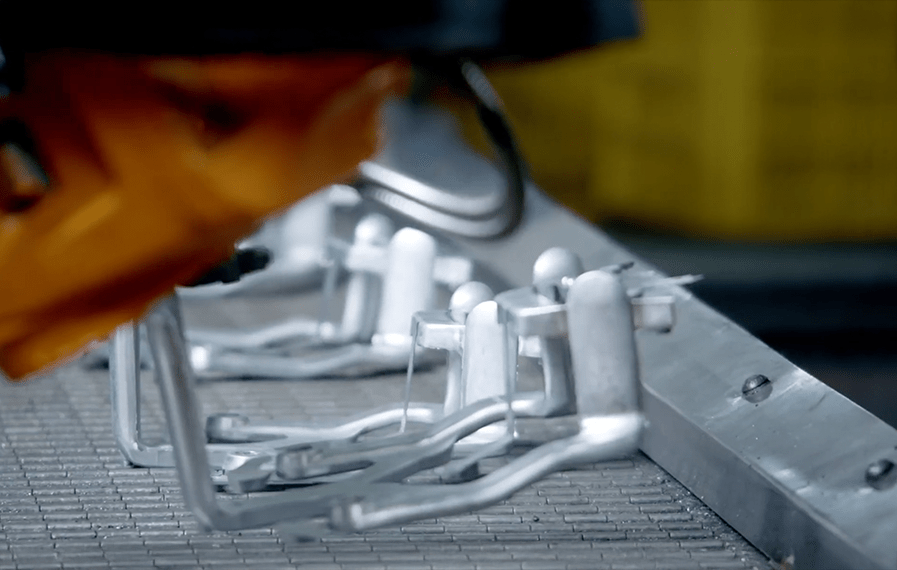

Aluminum alloys can be easily cast into complex shapes with excellent precision and smooth surface finishes. This flexibility allows for the production of intricate designs, which is a major benefit in industries that require customized parts with high dimensional accuracy.

- Aluminum Die-Cast Components for Drones

- Aluminum Die Casting Parts for Low Earth Orbit Satellites

- High-Performance Thermal Components for AI

- From Concept to Mass Production: How Advanced Patent Die Casting Enables Complex Industrial Designs in the AI Era

- Supply Chain Resilience and Localized Manufacturing: Why "Made in Taiwan" Aluminum Die-Casting Parts Are Gaining Favor Post-Pandemic

- New Opportunities in Aluminum Die-Casting Amidst the EV and New Energy Wave: How Lightweighting is Defining the Future of Mobility

- Unveiling the Future of Aluminum Die-Casting: How Industry 4.0 is Revolutionizing Production Efficiency and Quality

- Why Aluminum Alloys Are Preferred for Die-Casting?

- Alunex OEM/ODM Die-Casting Solutions for Automotive, Motorcycle, and Bicycle Parts

- ALUNEX's OEM/ODM Expertise: Tailored Heat Sinks for Your EV Applications

- Die Casting Development Process at ALUNEX

- Things to Consider During Aluminum Die-Casting Processing

- What Industries Can Die-Casting Serve?

- Features of Aluminum Die-Casting

- Why Choose Aluminum Alloy as the Die-Casting Material?

- What is Aluminum Die-Casting?

- Unlocking the Future of Die Casting: The Advantages of CNC Machining for Post-Casting Operations

- Order Issues and Support