From Concept to Mass Production: How Advanced Patent Die Casting Enables Complex Industrial Designs in the AI Era

With the widespread adoption of AI-assisted design tools, industrial designers and engineers are now able to create innovative and highly intricate product structures that were once unimaginable. These designs often feature biomimetic shapes, topology-optimized structures, ultra-thin walls, or complex multi-cavity configurations. While they excel in both aesthetics and functionality, such products frequently encounter obstacles when it comes to mass production—mainly due to the limitations of traditional manufacturing techniques.

The crucial challenge facing today’s industrial design and manufacturing sectors is how to effectively transform these AI-driven design concepts into mass-producible, tangible products. Overcoming this barrier is key to unlocking the full potential of next-generation industrial innovation.

ALUNEX’s Patented Die Casting Process: Making Complex Designs Possible

When it comes to overcoming highly challenging die casting requirements, ALUNEX CASTING ENTERPRISE CO., LTD. leverages its unique patented casting process and equipment to create a seamless bridge from creative concept to mass production. This patented technology is more than a blend of advanced machinery—it represents an innovative methodology that unites precision mold design, meticulous control of metal flow, and intelligent production monitoring. This enables ALUNEX to transcend the limitations of traditional die casting, realizing unprecedented accuracy and complexity for intricate components, ultra-thin walls, and multi-cavity parts.

- Breakthroughs in Irregular Structures and Ultra-Thin Walls: Through the precise control of molten metal flow, pressure, and cooling speed, ALUNEX’s patented process ensures optimal metal filling even for parts with wall thicknesses below 1mm or highly irregular geometries. This technology effectively prevents defects such as shrinkage and porosity, while maintaining outstanding dimensional stability.

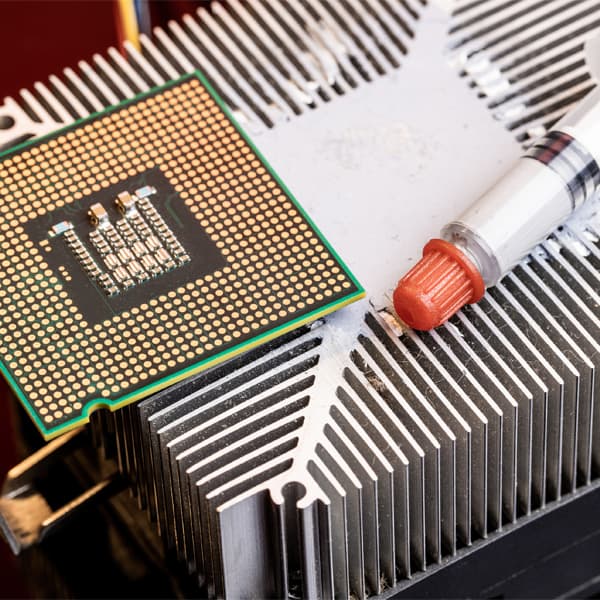

- Multifunctional and Multi-Cavity Designs: For parts featuring complex internal structures or requiring integrated functionality, ALUNEX uses patented mold designs and advanced core-pulling techniques to achieve precise molding of hollow or multi-cavity components. This not only meets the needs for thermal management and fluid transfer but also significantly shortens production cycles and reduces costs.

- Process Optimization and Intelligent Monitoring: ALUNEX incorporates smart monitoring technologies into its production line, enabling real-time analysis and automatic adjustment of casting parameters. This further boosts product quality and manufacturing efficiency, making the company especially adept at handling innovative designs that demand the highest levels of precision.

With these patented innovations, ALUNEX CASTING ENTERPRISE CO., LTD. continues to set new industry benchmarks, turning the most ambitious, AI-driven designs into reliable, mass-produced industrial reality.

Collaborative Innovation: Turning the Impossible into Reality

ALUNEX CASTING ENTERPRISE CO., LTD. is more than just a manufacturer—it is a strategic partner in customers’ product development journeys. We understand that the full potential of AI-driven design can only be realized through seamless integration between design and manufacturing. From the earliest concept stages, our experienced engineering team works closely with clients’ designers and R&D personnel, conducting in-depth manufacturability assessments and mold flow analyses. This proactive, collaborative approach allows us to foresee and resolve potential production challenges during the design phase, significantly reducing the time from concept to mass production.

One notable example involved a leading technology company that leveraged AI to design an ultra-lightweight chassis component featuring a biomimetic, bone-like internal structure. Due to its ultra-thin walls and intricate internal channels, several traditional manufacturers deemed the design unfeasible. Upon accepting the challenge, ALUNEX’s team re-engineered the mold gating and cooling systems, and precisely controlled the die casting parameters using our patented processes. Ultimately, we turned what seemed like an impossible blueprint into a mass-produced aluminum die-cast component that delivered both lightness, structural strength, and top-tier quality—giving our customer a significant market edge.

Pushing Boundaries, Achieving Excellence

In this new era of AI-driven design, the limits of manufacturing are constantly being redefined. With a spirit of relentless innovation and a belief that “nothing is impossible,” ALUNEX views each challenging die casting project as an opportunity to surpass ourselves. We encourage industrial designers, product development engineers, and R&D leaders to bring us their most ambitious and demanding concepts. Supported by our patented casting process and expertise in mold design and process optimization, we are your steadfast partner—from creative concept to finished product—in turning the boldest ideas into reality.

- Aluminum Die-Cast Components for Drones

- Aluminum Die Casting Parts for Low Earth Orbit Satellites

- High-Performance Thermal Components for AI

- From Concept to Mass Production: How Advanced Patent Die Casting Enables Complex Industrial Designs in the AI Era

- Supply Chain Resilience and Localized Manufacturing: Why "Made in Taiwan" Aluminum Die-Casting Parts Are Gaining Favor Post-Pandemic

- New Opportunities in Aluminum Die-Casting Amidst the EV and New Energy Wave: How Lightweighting is Defining the Future of Mobility

- Unveiling the Future of Aluminum Die-Casting: How Industry 4.0 is Revolutionizing Production Efficiency and Quality

- Why Aluminum Alloys Are Preferred for Die-Casting?

- Alunex OEM/ODM Die-Casting Solutions for Automotive, Motorcycle, and Bicycle Parts

- ALUNEX's OEM/ODM Expertise: Tailored Heat Sinks for Your EV Applications

- Die Casting Development Process at ALUNEX

- Things to Consider During Aluminum Die-Casting Processing

- What Industries Can Die-Casting Serve?

- Features of Aluminum Die-Casting

- Why Choose Aluminum Alloy as the Die-Casting Material?

- What is Aluminum Die-Casting?

- Unlocking the Future of Die Casting: The Advantages of CNC Machining for Post-Casting Operations

- Order Issues and Support