Advancements in Aluminum Die-Casting Technology for Heat Sinks in Aerospace

As innovation continues to shape the future of aerospace, the evolution of thermal management solutions plays a crucial role in optimizing performance, safety, and sustainability. In this rapidly advancing landscape, aluminum die-casting technology has emerged as a game-changer, particularly in the design and manufacturing of heat sinks for aerospace applications. With its impressive strength-to-weight ratio and versatility, aluminum is becoming an increasingly essential material for modern aerospace systems, including electric Vertical Takeoff and Landing (eVTOL) aircraft and air taxis.

At the heart of these innovations is the need for effective heat dissipation. As aerospace systems, especially fully electric aircraft, rely on high-performance electrical components and power systems, managing heat becomes critical. Efficient thermal management systems, including heat sinks, play a vital role in maintaining the optimal operating temperature of electronic components, preventing overheating and ensuring system reliability.

Why Aluminum Die-Casting is Ideal for Aerospace Heat Sinks

One of the primary advantages of aluminum die-casting for aerospace applications is its excellent strength-to-weight ratio. In industries like aerospace, where every gram counts, aluminum's lightweight nature allows for the design of parts that are both strong and durable, without adding unnecessary weight. The ability to produce complex geometries with thin walls, intricate internal structures, and sharp edges makes aluminum die-casting particularly suitable for heat sinks that need to be efficient yet lightweight.

The thermal conductivity of aluminum further enhances its suitability for aerospace heat sinks. Aluminum efficiently dissipates heat away from sensitive components, helping to regulate temperatures within the systems. When combined with advanced aluminum alloys, the material's inherent properties can be optimized to handle the demanding conditions in aerospace, from high-speed flight to extreme temperature fluctuations.

ALUNEX Leading the Way in Advanced Die-Casting for Aerospace

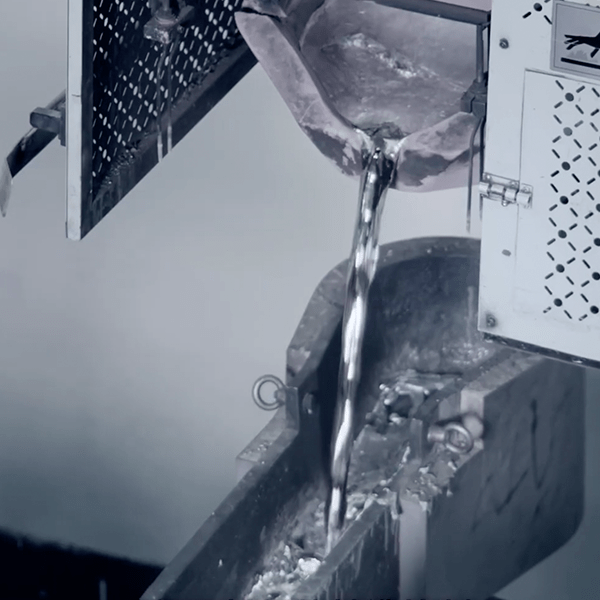

We are at the forefront of innovation in aluminum die-casting technology, integrating traditional die-casting methods with state-of-the-art advancements to meet the precise needs of the aerospace industry. By utilizing intelligent die-casting machines integrated with automated workflows, we are able to achieve higher consistency, repeatability, and accuracy in every casting. These advancements help us produce high-quality, high-performance aluminum components, such as heat sinks, that are critical for the efficiency of aerospace systems.

Our OEM/ODM capabilities allow us to provide customized solutions tailored to the specific thermal management requirements of each project. Whether it’s for eVTOLs, air taxis, or other aerospace systems, we offer flexibility in material choices, using both pure aluminum and aluminum alloy die-casting to meet the diverse needs of our clients. The precise manufacturing process, combined with our advanced quality control systems, ensures that each heat sink component meets the highest standards of reliability, efficiency, and durability.

Precision, Performance, and Efficiency in Heat Sink Design

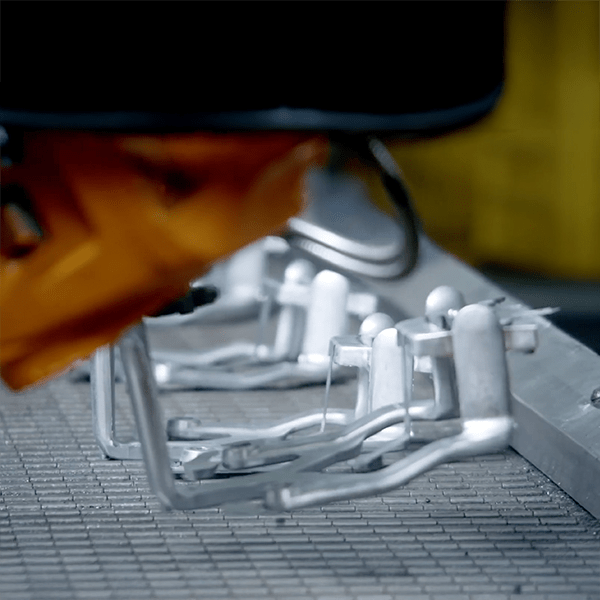

Aluminum die-casting for heat sinks requires the ability to manufacture components with complex internal structures that are both lightweight and efficient in heat dissipation. With the increasing demand for smaller, more powerful components in aerospace, the need for high-quality heat sinks that can manage heat in compact, high-density systems is more crucial than ever.

Our advanced die-casting technologies allow us to design and produce heat sinks that feature optimized surface areas, ensuring maximum heat transfer efficiency. The use of aluminum alloys with superior thermal conductivity enables these components to effectively manage the heat generated by power systems, motors, and electronics in eVTOL aircraft and other aerospace applications. The result is a cost-effective, lightweight, and high-performance solution for thermal management.

Shaping the Future of Aerospace Thermal Management

As the aerospace industry moves toward fully electric aircraft and next-generation propulsion systems, the need for advanced thermal management solutions will only grow. ALUNEX is excited about the potential of aluminum die-casting technology to support the next wave of innovation in aerospace, from eVTOLs to air taxis and beyond.

Our commitment to excellence in aluminum die-casting ensures that our heat sink solutions are optimized for performance, energy efficiency, and sustainability. As part of our ongoing dedication to innovation, we continue to refine our processes, incorporate emerging technologies, and push the boundaries of what is possible in aerospace thermal management.

If you’re looking for a trusted partner to provide precision-engineered aluminum heat sinks for your aerospace applications, ALUNEX is here to help. With our expertise in OEM/ODM, advanced die-casting capabilities, and a focus on delivering the best thermal solutions, we are ready to support your aerospace thermal management needs—today and in the future.

Contact us today to discuss your requirements and explore how our aluminum die-cast heat sinks can enhance the efficiency and performance of your aerospace systems.