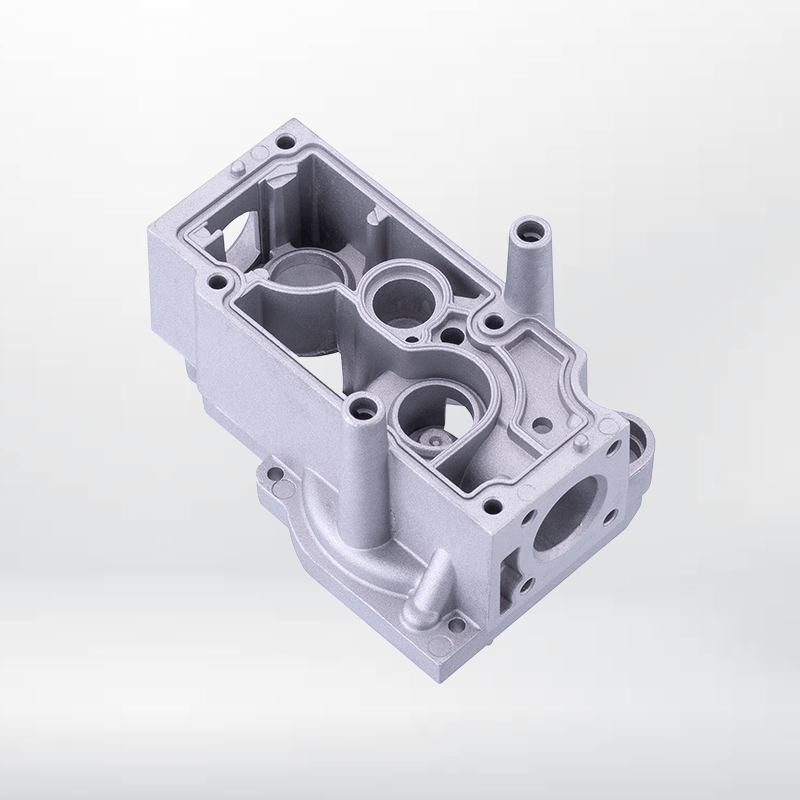

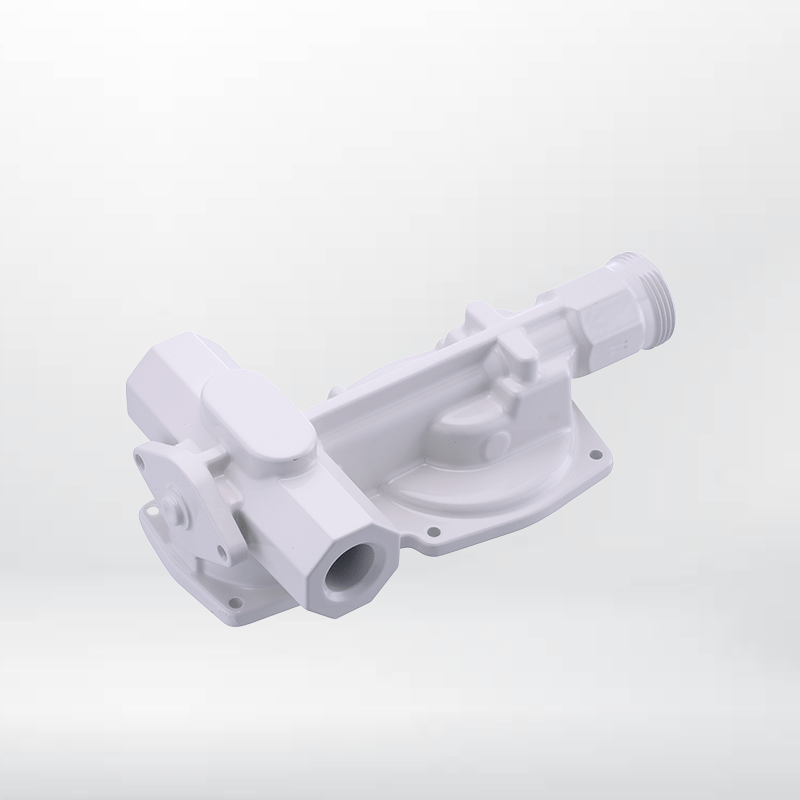

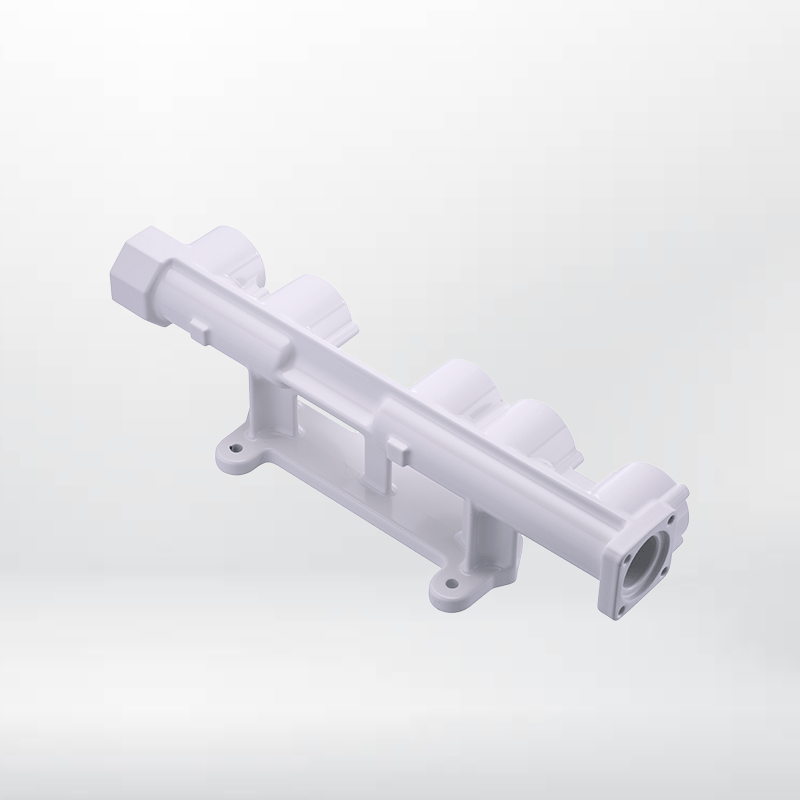

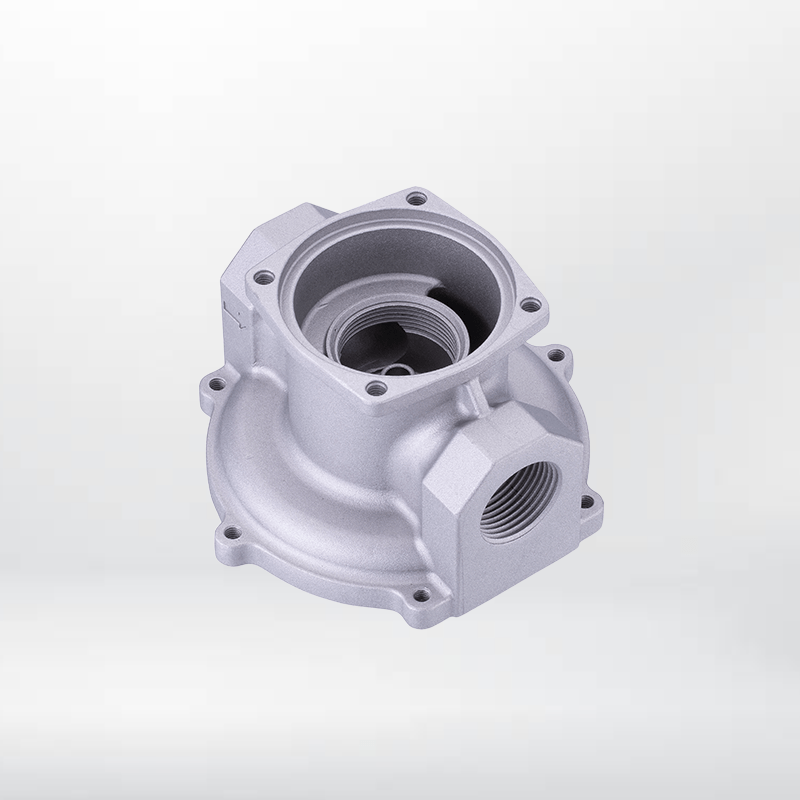

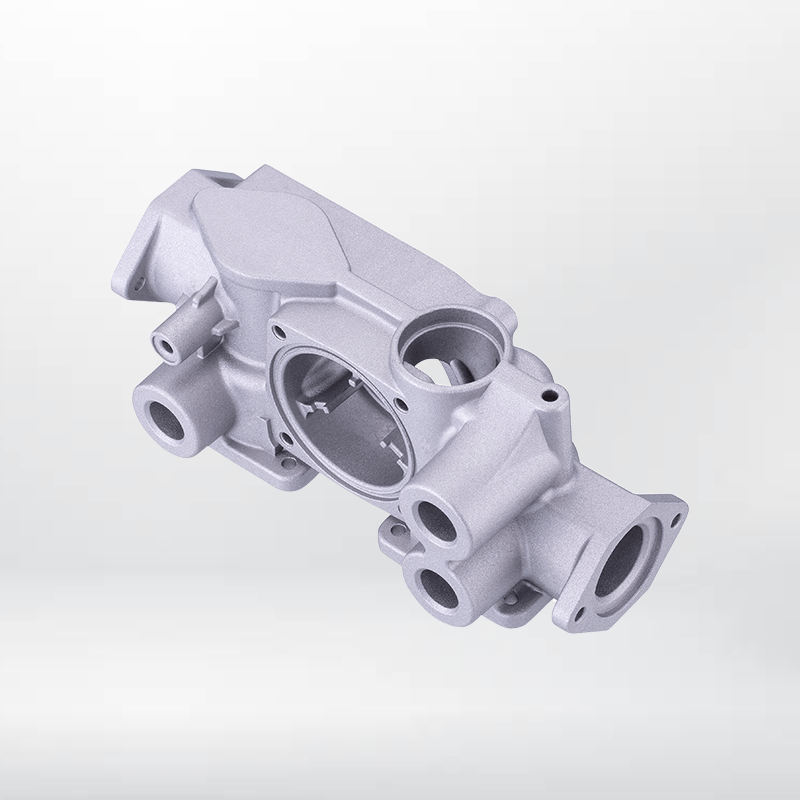

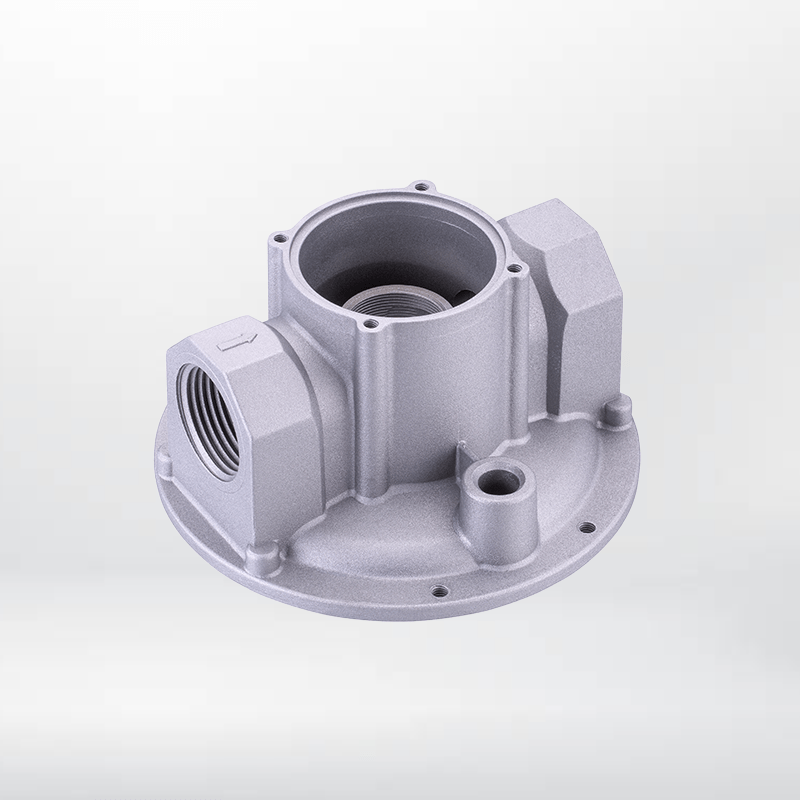

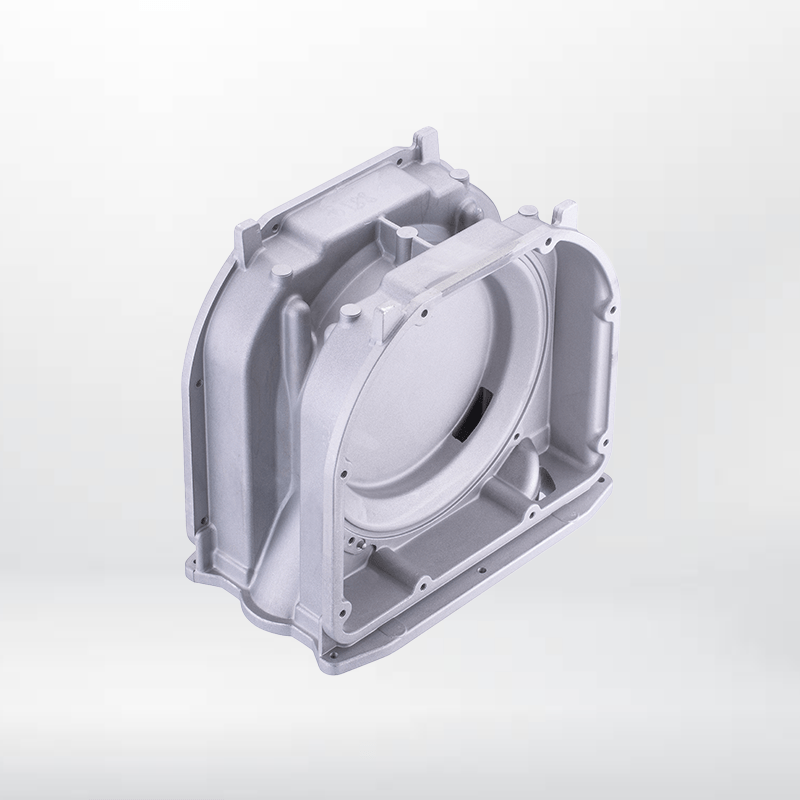

Gas Valve

High Precision and Tight Tolerances:

Aluminum die-casting enables the production of highly precise components with complex shapes and fine details, such as intricate internal passageways for gas flow or fine threads for fittings. This level of precision is essential for maintaining the operational efficiency and safety of gas equipment. In gas meters and regulators, for example, a perfect seal and precise internal geometry are necessary to ensure accurate readings and pressure regulation.

Temperature Stability and Reliability:

Gas equipment often operates in environments with wide temperature fluctuations, from sub-zero temperatures in outdoor installations to high temperatures in industrial settings. Aluminum’s excellent thermal conductivity and stability across a broad range of temperatures ensure that our die-cast components maintain their integrity and performance, even in extreme conditions. Whether in freezing cold or under high thermal stress, aluminum parts retain their mechanical properties and do not warp, crack, or lose strength.